Life cycle Assessment (LCA)

Lifecycle Assessment (LCA) to reduce environmental impact

Nissan identifies potential risks by conducting life cycle assessment (LCA). The LCA method is used to quantitatively evaluate and comprehensively assess environmental impact, not only during vehicle use, but at all stages, including raw material extraction, manufacturing and transport, as well as reuse or end-of-life vehicle recycling and by carrying out LCA for new technologies.

Our LCA methods received certification from the Japan Environmental Management Association for Industry until 2012. Since 2013, they have been certified by the third-party organization TÜV Rheinland in Germany, with the certification being renewed in December 2023. The latter certification is based on ISO 14040 and ISO 14044 standards and validates the environmental impact calculations in our product LCA.

Through the continuous implementation of LCA, we will promote the visualization and reduction of environmental impacts throughout the lifecycle of cars.

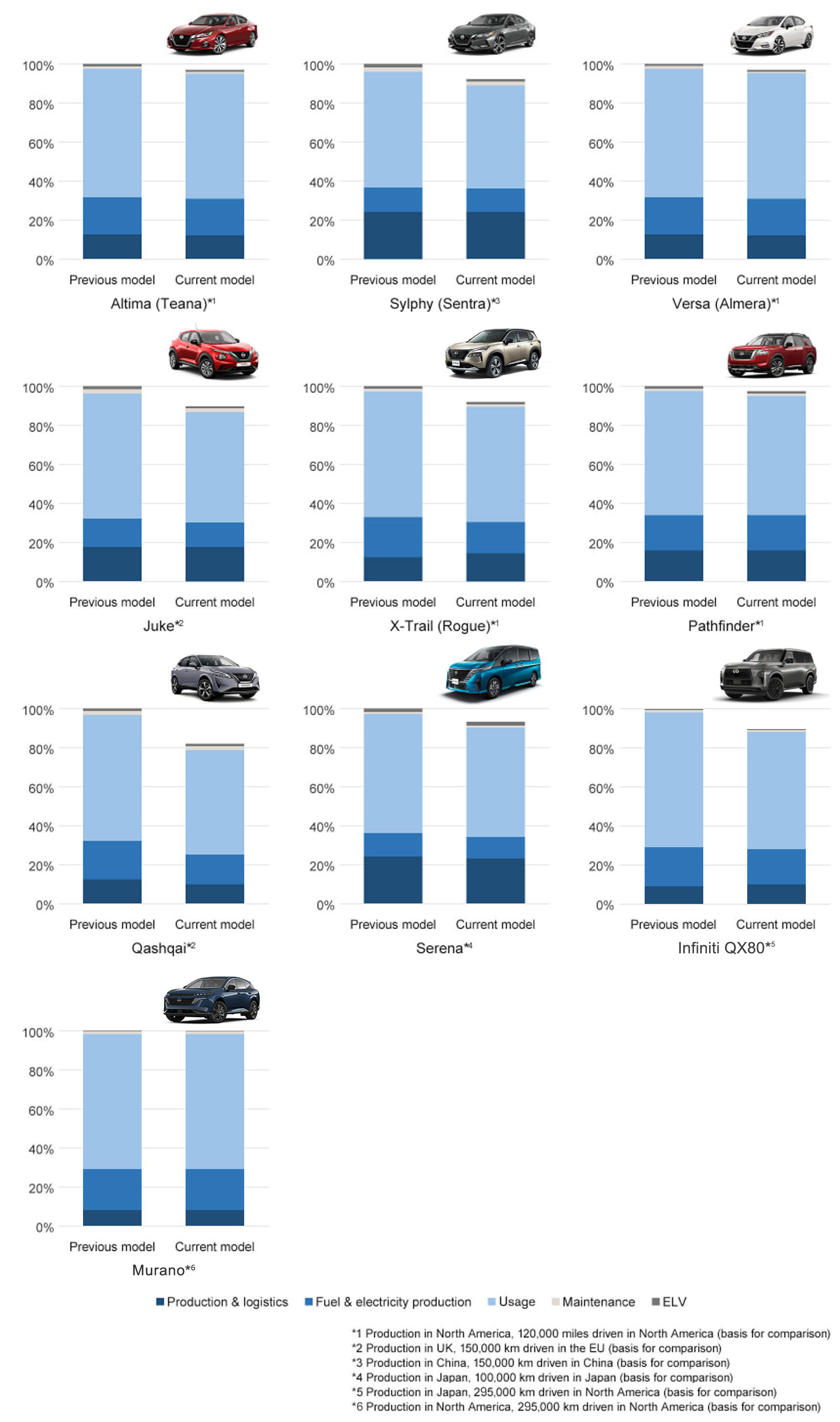

CO2 emissions over the life cycle of ICE vehicles

Nissan is continuously improving internal combustion engine (ICE) vehicle performance. DST (down-sizing turbo) engine is a one of examples, it is applied to new Juke and new X-trail (Rogue) and reduced around 10% CO2 emission due to substantial fuel economy improvement. The new Qashqai in Europe resulted approximately 20% CO2 reduction by appling mild-hybrid system. The new Pathfinder in US and new Serena in Japan, foundation technologies are applyed to reduce environmental impact like idling stop system, reducing several type of resistance, lighten vehicle weight etc. In addition, the new Murano in US has been updated with a wide cabin space and the latest technologies that represents ProPILOT, and the CO2 emissions have been reduced to the same level as the previous model by updating the powertrain etc.

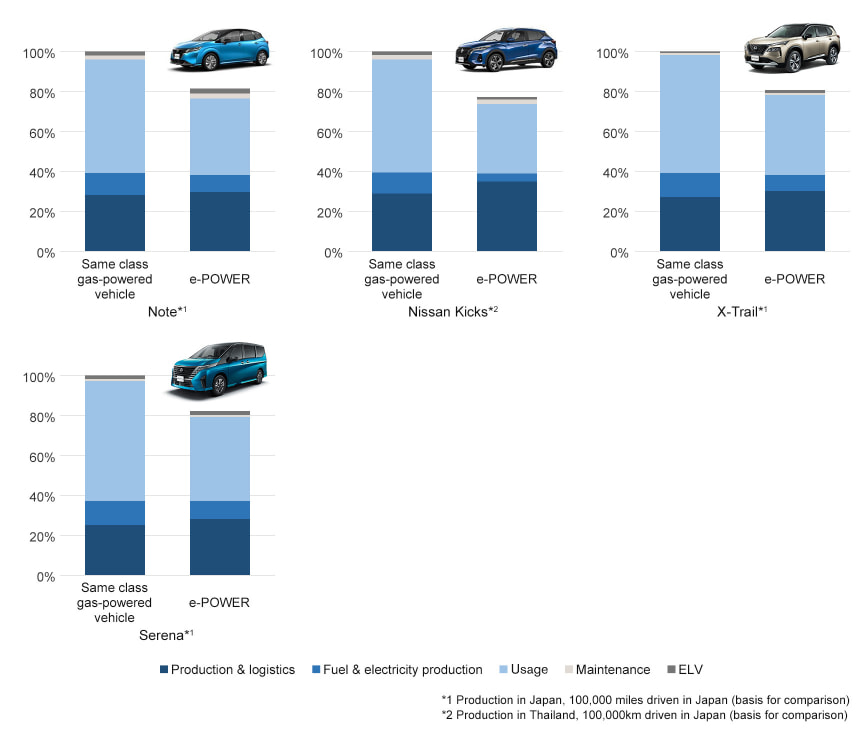

CO2 emissions over the life cycle of e-POWER vehicles

Nissan introduced its new e-POWER powertrain in 2016, marking another significant milestone in the electrification strategy with life cycle emission improvements. Compared to their gasoline-powered counterpart models, Note e-POWER, Kicks e-POWER, X-Trail e-POWER and Serena e-POWER emit approximately 20% less life cycle CO2.

Note e-Power which is launched in November 2020, improved simultaneously life cycle emissions and power efficiency by the second generation e-POWER. X-Trail e-POWER launched in July 2022 achieved all of powerful driving, quietness, feeling safe on every road condition and pleasant ride comfort, without environmental negative impact by second generation e-POWER, VC-Turbo engine and the e-4ORCE, an electric-drive four-wheel-control system. Serena e-POWER, launched in April 2023, reduced not only running but also production CO2 emission thanks to combination with second generation e-Power with newly developed exclusive engine and low-CO₂ blast furnace steel on several body structure parts which eliminates CO2 emissions from the manufacturing process.

Electrified e-POWER vehicles use a system which is supported by a gasoline engine as a power generation source. Since the engine only operates under certain fixed conditions, it is possible to achieve lower exhaust emissions and better fuel efficiency for driving. Also e-POWER achieve to save environmental impact on production slightly high level that of conventional vehicles because of less battery capacity compared with 100% electric vehicle. We promote further CO2 equivalent emission reduction with additional vehicle weight reduction and optimization of running energy efficiency with e-Power system.

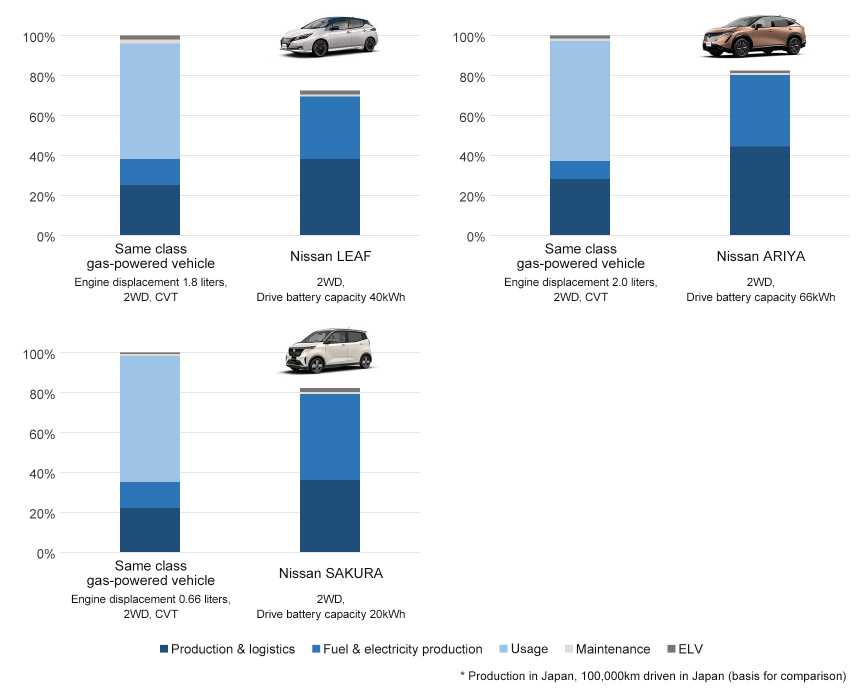

CO2 emissions over the life cycle of electric vehicles

The Nissan LEAF reduces its lifecycle CO2 emissions by approximately 30% compared to conventional vehicles of the same class in Japan.

The Nissan Ariya launched in 2022 achieves both further improvement of EV product performance and reduction of environmental impact. It extends EV driving range and reduces lifecycle CO2 emissions by approximately 20% compared to same segment gasoline-powered models in Japan.

The Nissan SAKURA is 3rd model as Nissan mass production EV and reduces approximately 20% lifecycle CO2. It keeps compact body, but also implemetns enough EV driving range for daily use and affordable price to accelerate EV spreading.

Nissan has enhanced carbon reduction attempt through ARIYA's vehicle life cycle.

Nissan keeps continuously to reduce CO2 emission from EV production process by improving the yield ratio of materials and increasing the use of recycled materials. On top, by introducing the Nissan Intelligent Factory to our Tochigi-plant, Nissan accelerate carbon neutrality in manufacturing with improving productivity in vehicle assembly, energy efficiency and electrification with uses of electricity generated from renewable energy sources.

To reduce environmental load in vehicle use, Nissan continually reducing CO2 emissions by improving efficiency of electric powertrains including battery, power savings on accessories and increasing renewable energy usage.

Nissan is also promoting vehicle battery reusing to realize the decarbonization of whole society as a stationary battery for distributed power supply to storage various renewable energies.

Nissan will keep reducing the environmental impact from the entire life cycle of electric vehicles.