Nissan has strived to be a leader in automotive technology since its founding 90 years ago, and artificial intelligence is no exception. As customer and societal needs continue to change rapidly, the Yokohama Lab is at the forefront of Nissan’s AI research and development, where AI and cars meet.

What is Yokohama Lab?

Yokohama Lab is a research center in Kanagawa Prefecture, Japan that studies how to utilize AI in automotive manufacturing. Modern AI, based on big data, excels at analyzing and expressing information in cyberspace. However, our products — vehicles — exist in the real world. The Yokohama Lab’s mission is to ensure that the results obtained through AI can be applied and utilized in actuality, rather than being limited to cyberspace.

Yokohama Lab Team

How will AI change car manufacturing?

It’s become clear that AI can be applied in various fields, including R&D, vehicle production and even design. At the Yokohama Lab, we are constantly exploring various ideas to see if AI can help solve the challenges faced by engineers and designers.

A predictive model for aerodynamics, which has significantly reduced computation time, is one example.

What is aerodynamics?

Simply put, aerodynamics is the way an object moves through air. Aerodynamic performance includes drag, the force exerted by air on the front of an object. Have you ever crouched down on a bicycle to cut through strong headwinds? You were reducing drag, and that’s crucial for cars as it significantly affects mileage and ride comfort.

Aerodynamic performance is currently evaluated by performing repetitive and complex calculations on powerful computers. These calculations predict performance indicators and show airflow. They form one of the simulation techniques in car manufacturing.

To achieve more accurate results through simulation, a vast number of intricate calculations is required. These calculations can require running hundreds of computers for several days.

Seeing Airflow.

As aerodynamics computer-aided engineering expert Kei Akasaka explains, "It’s now very challenging to quickly respond to sudden requests from designers. They can make slight changes to the design and want to know as soon as possible how it impacts aerodynamics.'"

Aerodynamics Engineer Kei Akasaka

Can AI solve the problem?

Akasaka approached the Yokohama Lab with a question: "Can we solve this problem using AI?"

A collaborative project was initiated to develop a prediction model using AI deep learning that could quickly estimate the drag coefficient around a car, but they soon ran into a problem. Training an AI model this way requires a massive amount of data, often needing tens of millions of computers. Unfortunately, most of the old simulation data had been deleted and the small amount remaining wasn’t suitable for machine learning.

Chen Fangge, a data scientist, explains how they addressed the issue. "We recalculated everything from scratch. At the same time, we set rules for saving data specifically for machine learning during simulations and determined the requirements for data storage. It took us over a year to gather enough data to be used by the AI model."

Unfortunately, the amount of collected data proved insufficient to achieve the desired accuracy. They needed a different approach.

Chen says, “As the data increases, the accuracy improves, but it also increases dependency on the data. To tackle this, we experimented and worked with Akasaka, training the model with paired information such as fluid dynamics equations and other physical laws in addition to the shape of the car."

Reducing prediction time to seconds

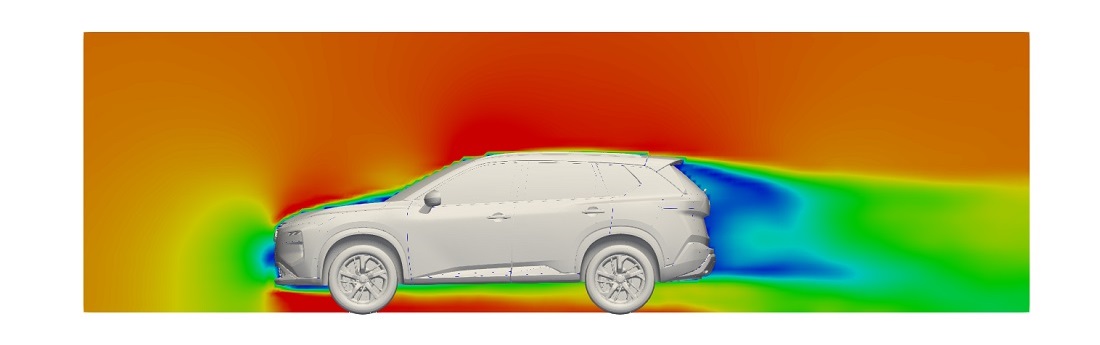

Simulation Image Using AI Prediction Model

In this research, AI was able to dramatically shorten the duration of simulations by learning the relationship between the shape of the car and its aerodynamic performance based on a large amount of data. Predicting the aerodynamic performance of a new car design could now be done in a few seconds instead of several days.

By using this technology, designers and engineers can explore new designs in shorter cycles. This is expected to lead to creation of innovative vehicle body shapes that achieve a better level of balance between design and aerodynamics.

Exploring Ideas