Mode Control Vehicle Body Design Technology

The benefits of embracing a new mindset to structural design

A vehicle’s body rigidity is not only for structural integrity and impact performance, it can also support a quiet and comfortable ride experience. Balancing these characteristics provides a unique challenge to engineers. Elevating the body’s structural integrity and performance traditionally requires increases bracing and thus, increasing the vehicle’s body weight which can amplify road noise and vibrations. Optimizing for reduced vehicle body weight can introduce unwanted body flex which can make journeys uncomfortable for occupants.

To challenge this, Nissan engineers changed their development mindset, from a perspective of focusing only on structural rigidity to a broader approach that targets comfort and peace of mind by minimizing body flex while also optimizing a vehicle’s structure rigidity.

Technology configuration

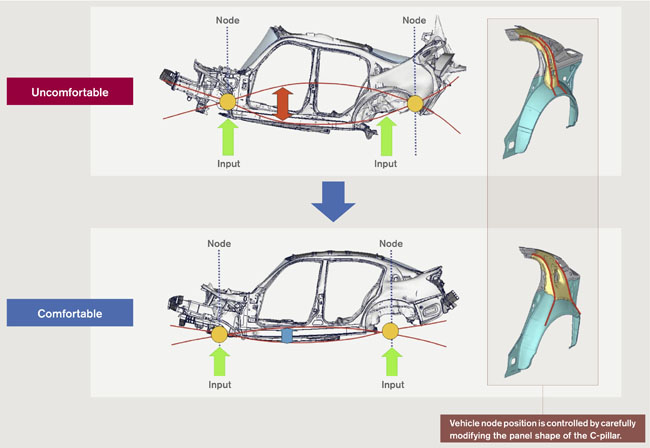

As part of a body’s design, there are key structural fixed points called, “Nodes”. Nodes do not flex, so when force is applied to them, such as force moving upward from the road, they can amplify vibrations that impact cabin comfort. Nissan engineers have minimized this by optimizing the panel thickness and positioning of nodes to diffuse and distribute forces evenly throughout the body structure. The result is a more comfortable, relaxing ride for occupants.

To further improve the quietness, the floor panels were also redesigned to reduce vibrations transmitted from the road. By using strategic curved panel shapes and bead welds in optimal positions that disperse strain and sound resonance, vibration suppression has been enhanced.

Example of mode control design technology

Example of floor panel design