All-solid-state batteries

High-quality battery technology that dramatically boosts the performance of EVs

In its long-term vision, Nissan Ambition 2030, Nissan announced that, by FY2028, it aims to launch an electric vehicle (EV) with all-solid-state batteries (ASSBs) that have been developed in-house.

ASSBs are expected to be a game-changing technology for accelerating the popularity of EVs.

They have the potential for energy densities approximately twice that of conventional lithium-ion batteries, significantly shorter charging time due to superior charge/discharge performance, and lower cost realized by using less expensive materials. With these benefits, Nissan expects to use ASSBs in a wide range of vehicle segments, including pickup trucks, making its EVs more competitive.

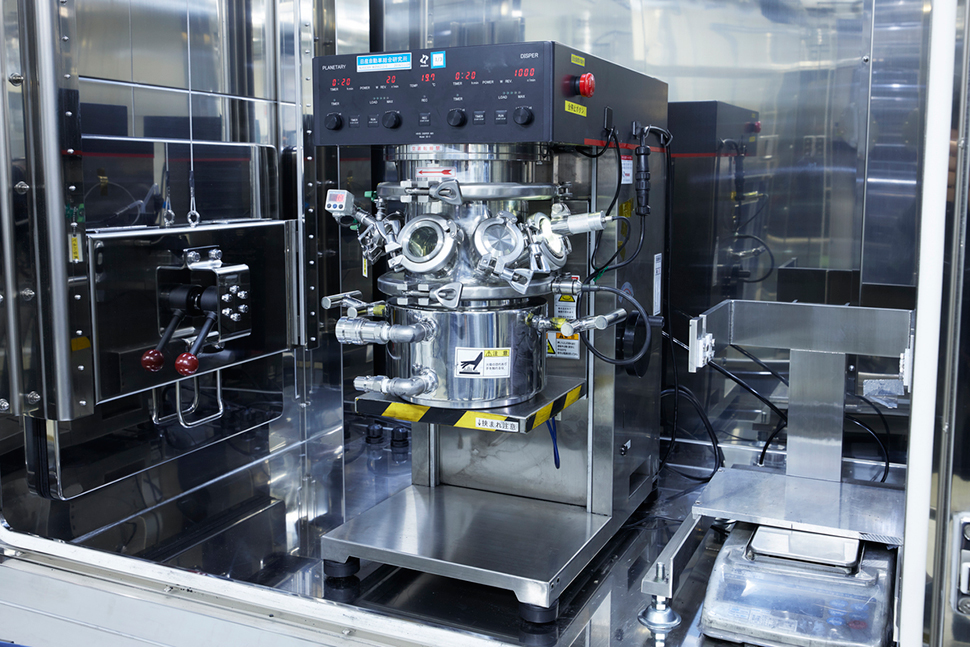

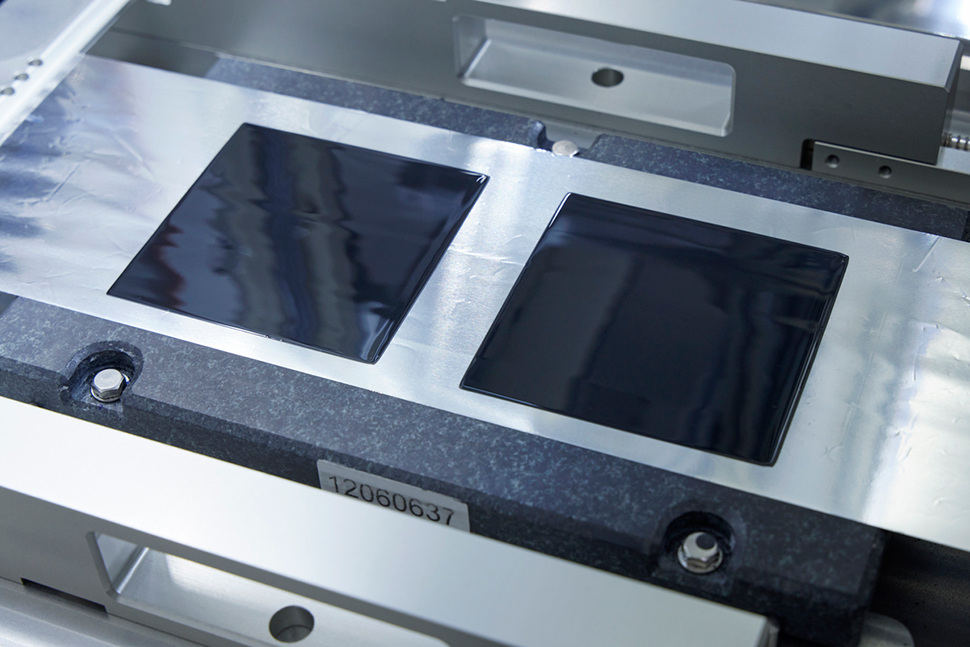

Nissan is conducting a wide range of R&D activities, from molecular-level battery material research to electric vehicle development, and even city development using EVs as storage batteries. Utilizing the knowledge gained from past experience, and our own prototype production facilities for all-solid-state batteries, we will be stepping up development with the goal of practical implementation.

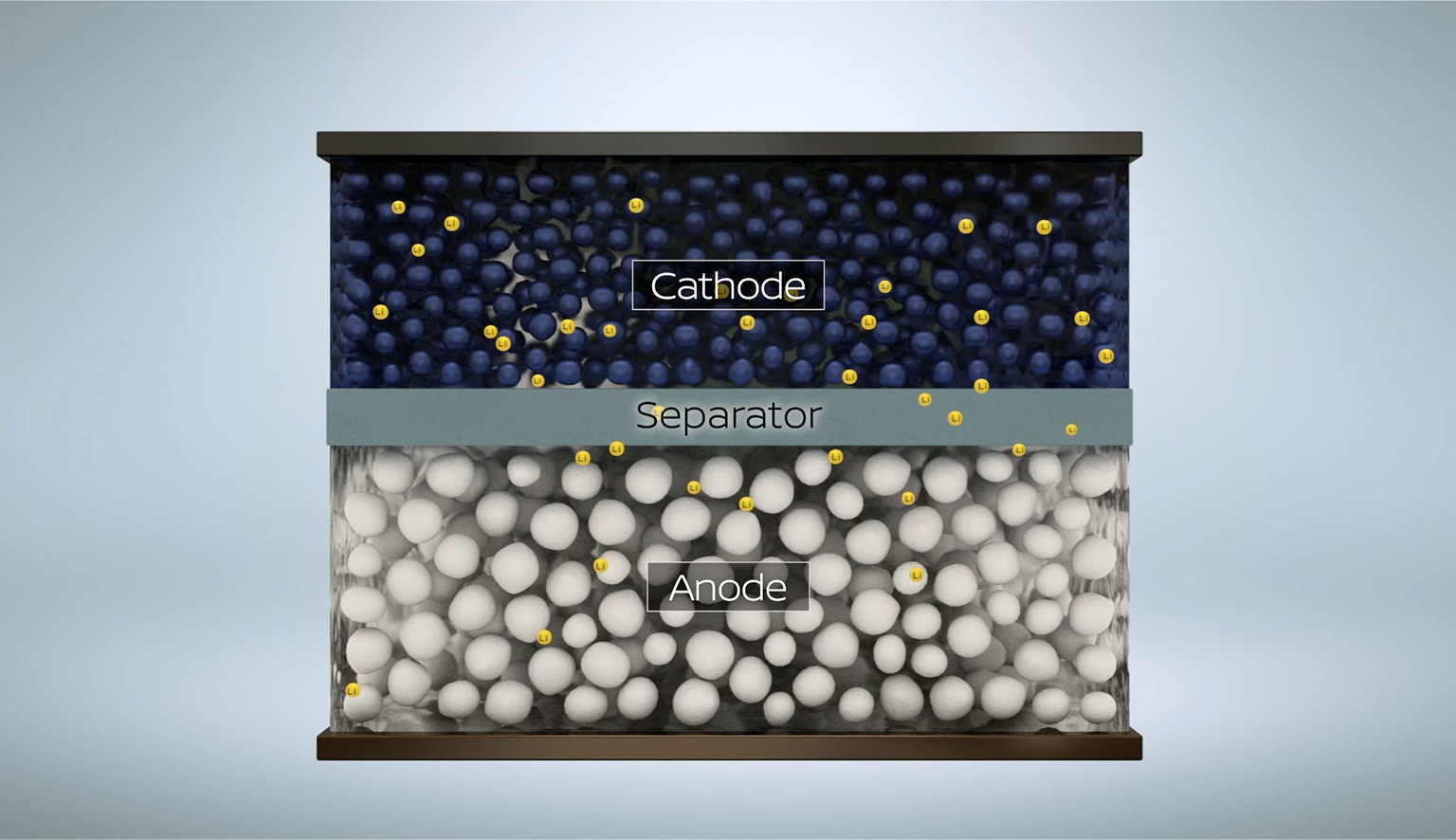

Basic operation of a lithium-ion battery

A lithium-ion battery is charged by lithium ions moving from the positive electrode (cathode) to the negative electrode (anode) and then discharged by them moving from the negative electrode (anode) to the positive electrode (cathode).

The cathode and anode act as lithium storage and affect energy capacity. The more lithium that can be stored, the greater the battery's capacity.

In addition, the electrolyte also has a significant impact on the speed at which lithium ions move, with faster lithium-ion movement contributing to higher battery output and shorter battery charging times.

Cathode/Anode: Lithium-ion storage = Factor affecting energy capacity

Electrolyte: Lithium-ion movement rate = Factor affecting battery output

and battery charging times

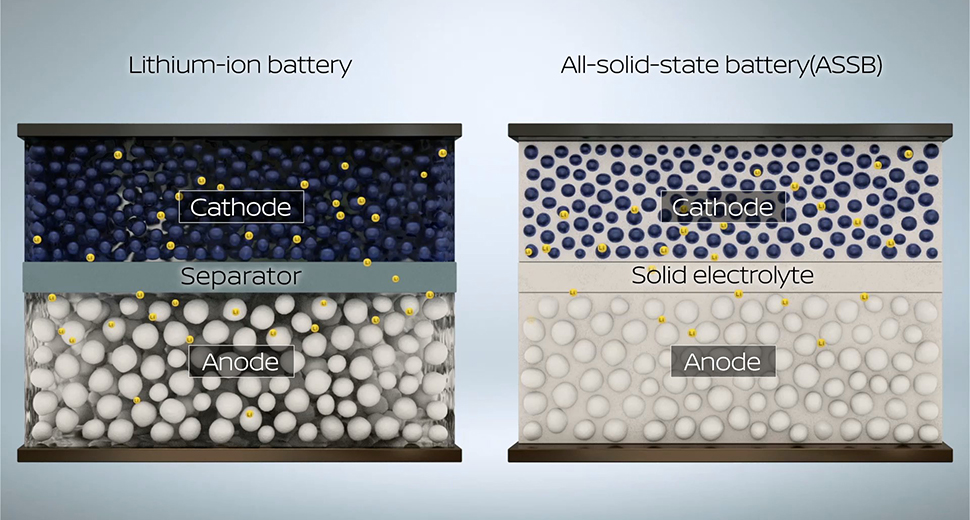

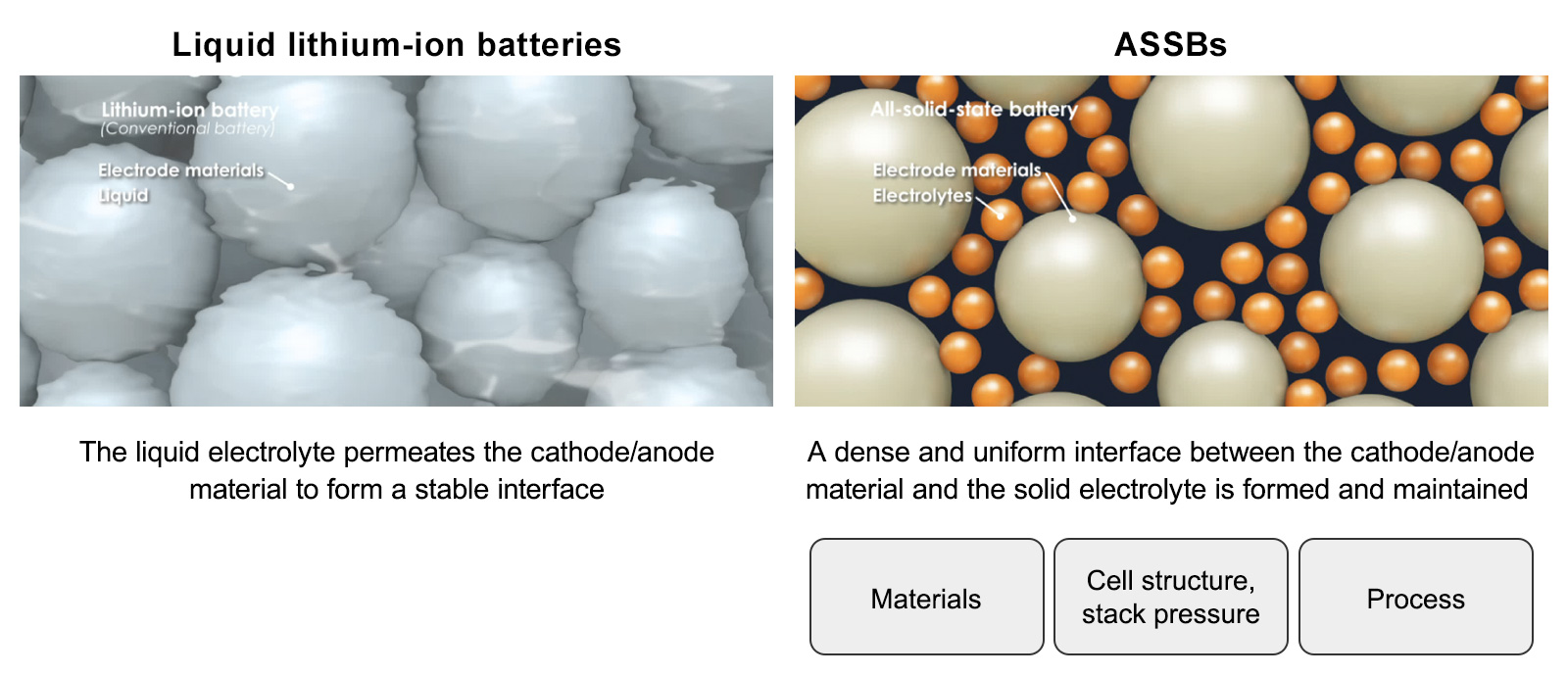

Compositional differences between liquid lithium-ion batteries and ASSBs

Liquid lithium-ion batteries use a liquid (an organic solvent) as the electrolyte. While liquid electrolyte can easily penetrate inside the cathode/anode and conduct lithium, high temperatures accelerate the chemical deterioration of the electrolyte, and the flammability of organic solvents can cause accidents, such as ignition, in the event of a malfunction.

On the other hand, the electrolyte in an ASSB is solid, is not volatile or flammable, is generally said to be highly safe, is robust to temperature, and is resistant to deterioration.

Technical characteristics of ASSBs

Because liquid electrolytes use organic solvents, which have low boiling points and high volatility, there are operating temperature limits for charging and driving. However, ASSBs do not use liquid electrolytes, so they have high operating temperature limits and have excellent fast-charging performance.

With liquid electrolytes, there are restrictions on the materials that can be selected due to side reactions with the cathode and anode materials, but with solid electrolytes, there are fewer side reactions because of their solid nature, allowing for more combinations of materials. This makes it possible to select cathode materials with lower costs and anode materials with higher energy density.

Towards the practical application of ASSBs

Despite their outstanding technical characteristics, there are a variety of issues in the practical application of ASSBs.

For example, because a solid electrolyte takes the place of the electrolyte solution in an ASSB, the cathode/anode materials and the solid electrolyte must be uniformly distributed, the interface between the materials (formed between solids) must be maintained, and it is essential to select materials that meet these conditions. Additionally, in cell design, it is necessary to design surface pressures to maintain these conditions. Furthermore, it is critical to find conditions for uniform mixing in the production process.

In order to solve these problems, Nissan is taking a principles-based approach while conducting joint research with global experts in a variety of fields, such as identifying materials that use advanced computational science, incorporating theoretically-derived ideal materials into production-capable materials, and analyzing phenomenon that occur in prototype batteries, etc.

Nissan's prototype production facility for ASSBs