Toward Zero New Material Resource Use

Creating a system that circulates resources efficiently and sustainably, and promote services to circulates Vehicles more effectively (Circular Economy)

With the world’s population forecast to exceed 9 billion by 2050, demand for natural resources like minerals and fossil fuels is set to rise. This makes it even more important to maximize the value obtained from these resources. The Sustainable Development Goals adopted by the United Nations in 2015 also emphasize the importance of managing resources sustainably and using them efficiently.

Automobiles are made of many components, incorporating a diverse range of resources. The combination of these resources creates new value. Nissan has increased its resource diversification, using more renewable resources and recycled materials. While caring for ecosystems, Nissan became more competitive as we targeted green growth.

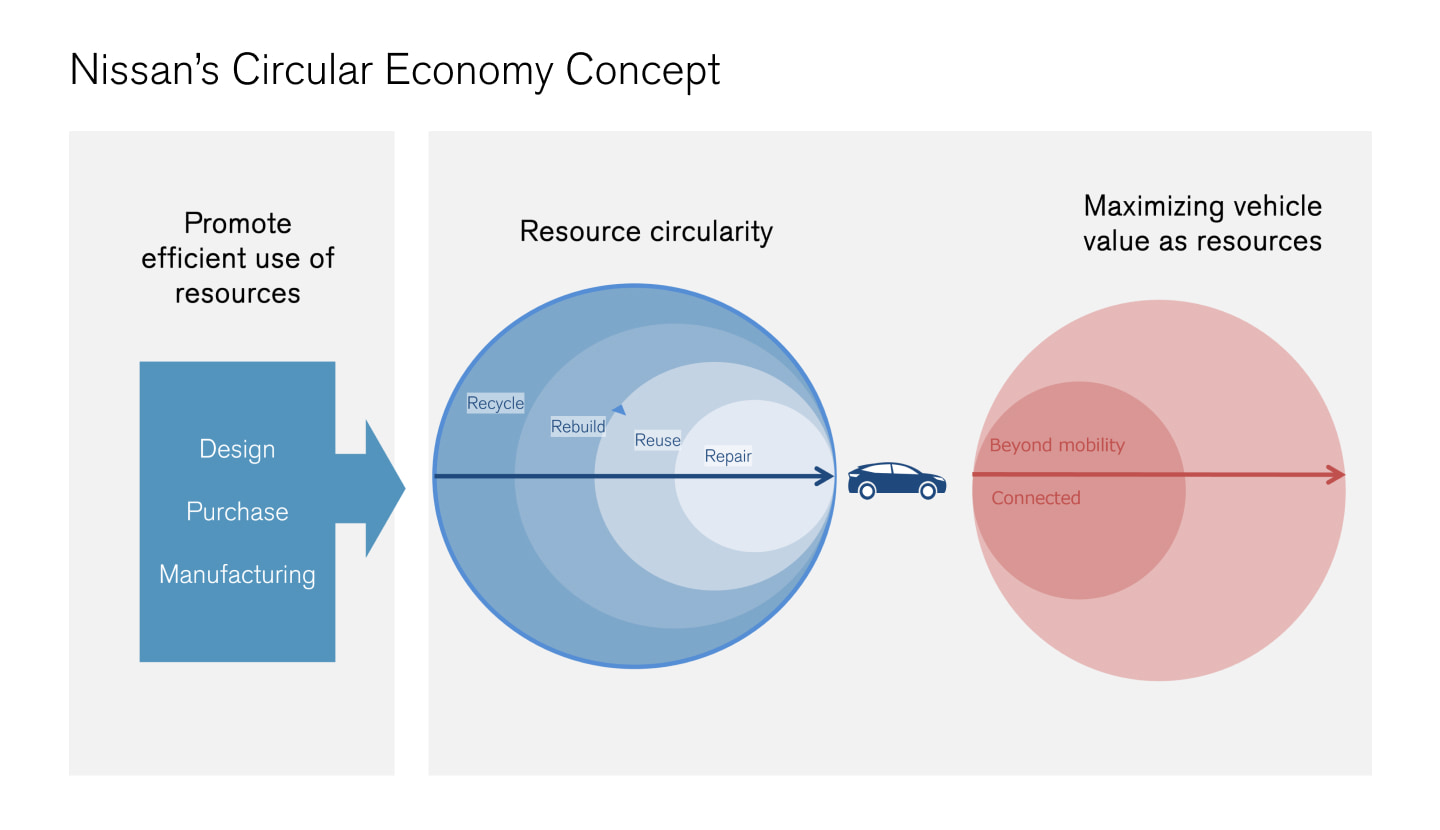

Nissan is committed to promoting the efficient and sustainable use of resources necessary for vehicle. Furthermore, we promote that maximizing the utilization of cars is an important endeavor for the efficient use of resources. To maximize the value provided to customers and society by developing systems that efficiently and sustainably utilize resources throughout the entire lifecycle, we have adopted the concept of a circular economy.

NGP2030 Objectives

| Activities | NGP2030 Objectives | |

|---|---|---|

| Material Resource | Expand Sustainable material (weight basis) | 40% (Japan, U.S.A., Europe and China) |

| Manage Waste / Landfill | ||

| Vehicle Usage | Expand Energy Management Function | Equipped rate to EV: 100% (Japan, U.S.A. and Europe) |

NGP2030 Main Activities

Nissan has set the following specific targets and plans for 2030 regarding particular important activities related to resources.

Initiatives to expand the adoption of sustainable materials

In order to achieve efficient resource utilization with minimal energy consumption, we are actively promoting the use of recycled materials, as well as encouraging the recycling of used automobiles. We are committed to resource reuse and considering resource conservation through proper utilization of chemicals and lightweighting of vehicles from the design, procurement, and production stages. Additionally, we are dedicated to promoting efficient resource utilization with minimal energy consumption by expanding repair and replacement options for customers, increasing the application of rebuilt parts, and expanding the reuse of electric vehicle batteries. Furthermore, we are advancing the development of bio-based materials, die-less forming, and expanding the adoption of green steel and green aluminum.

Initiatives to maximize the value of vehicles as resources

We are not only promoting electrification, autonomous driving, and connected technologies to maximize the utilization of cars, but also advancing the provision of new mobility services such as ride-sharing and utilizing cars as an energy source. These efforts aim to connect the utilization of cars with social value enhancement.