Improving efficiency

Nissan improves fuel efficiency of ICEs through the improvement of engine thermal efficiency, Continuously Variable Transmission (CVT) efficiency, weight reduction and electrification.

Variable Compression Turbo engine (“VC Turbo”) and CVT

The "VC Turbo" engine is able to freely change the compression ratio, which is the most important parameter determining efficiency and power. This makes it the world’s first mass produced engine to meet customer's demand for very low fuel consumption and high power, which are parameters usually in a trade-off relationship. The “VC Turbo” is currently being installed in the Infiniti QX50 and Altima in the US and China.

“Mirror bore coating” technology has been applied to improve the efficiency of gasoline engines, including the “VC turbo” engine. Instead of using a conventional cast iron cylinder liner, this technology reduces mechanical loss and weight by spraying molten iron on the inner wall of the cylinder where the piston moves up and down.

Detail of the VC Turbo engine in the Infiniti QX50 (Structure showing the multi-link system rotating the crankshaft)

Also, the Continuously Variable Transmission (CVT) is being promoted as a technology to improve fuel consumption through its “stepless” gear ratio change capability. Based on the vehicle speed, the CVT system can adjust the gear ratio to the most efficient engine rotation speed and deliver both smooth and powerful driving in low and high speeds, as well as low fuel consumption. Nissan uses CVT technology in a wide range of models, from mini-vehicles to medium sized cars, e.g., 3.5L class.

Smart Simple Hybrid and e-POWER

Powertrain electrification is advancing with the Smart Simple Hybrid system in the new Dayz, and e-POWER system in the Note and Serena.

The Smart Simple Hybrid technology improves fuel efficiency by capturing kinetic energy through regenerative braking using a motor connected to the engine with a belt, and reusing it for acceleration. The new Dayz increases the amount of regeneration by combining a high capacity lithium-ion battery, which ensures energy reuse without losses.

Note with e-POWER system

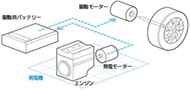

The e-POWER system in the Note and Serena is a new power unit that combines a gasoline engine and a motor, where the electricity generated by the gasoline engine is used to deliver power to the vehicle through the motor.

In the e-POWER system, the gasoline engine is not directly connected to the engine or wheels, making it possible to generate power at most efficient engine rotation speed and torque. It has excellent performance in improving fuel efficiency when driven in urban areas, where cars are frequently used.

In addition to fuel efficiency, the e-POWER is driven 100% by a high-power motor, which is also mounted on the Nissan LEAF in order to achieve quiet, powerful and responsive acceleration.

Generator, battery and motor in the e-POWER system

Toward Lighter Vehicles

Vehicle weight reduction makes important contributions to improve fuel efficiency. Nissan is promoting vehicle weight reduction by optimizing vehicle body structure, developing better forming and joining techniques and substituting materials.

In the field of material substitution, Nissan has put its own 1.2 gigapascal (GPa) Ultra High Tensile Strength Steel with High Formability, the world's first such material to combine these levels of tensile strength and workability, to use in the Infiniti Q50 (marketed in Japan as the Skyline) and the Murano in North America and, in 2016, in the Infiniti Q60. And in March 2018, Nissan became the first carmaker in the world to use Super High Formability (SHF) 980 megapascal (MPa) Ultra High Tensile Strength Steel for the front and rear members and other body frame parts of the Infiniti QX50 launched in the United States.

These Ultra High Tensile Strength Steel reduces the amount of material used while allowing production on the same lines, making it possible to create lighter cars with thinner components while reducing total costs. Nissan plans aggressively to expand the use of Ultra High Tensile Strength Steel, aiming for it to make up 25% of the company's vehicle parts by weight, and is actively pursuing new application technologies for it. The material makes up 27% of the new QX50 and enhances driving performance while reducing the vehicle's weight.

Nissan is developing weight reduction technologies for reducing CO2 emissions and reducing use of new material.

Projects to Ease Traffic Congestion with the Use of ITS

Fuel consumption is greatly affected by traffic circumstances and the way a car is driven.

We are actively working to bring about social infrastructure that will help to improve the traffic environment. This includes efforts to solve difficult road traffic problems, such as the alleviation of congestion, which cannot be achieved by individual automakers. We recognize the importance of intelligent transport systems (ITS) technology in overcoming these problems, and are working together with other industries for the practical realization of ITS.

What is ITS?

Intelligent transport systems use advanced communications technology to link information on humans, roads, and vehicles in a network, and reduce road traffic problems such as accidents and congestion. ITS can link with road communications equipment and other infrastructure, and use information on the status of nearby vehicles and the surrounding traffic environment to help raise fuel efficiency, alleviate congestion, and improve safety.

Projects using ITS

The SKY Project in Japan

Nissan began the SKY Project in October 2006 to reduce traffic accidents and ease congestion using ITS in Kanagawa Prefecture, a major Nissan hub. A significant feature of this project is the collection of real-world vehicle data from our customers to examine ways of raising energy efficiency by alleviating congestion and reducing CO2 emissions in daily driving.

The project is conducted in partnership with industries outside the automobile industry, and is moving ahead with the cooperation of related government agencies. Nissan hopes to successfully demonstrate the effectiveness of ITS in Kanagawa Prefecture, and to expand these systems to all of Japan and subsequently to the rest of the world. Nissan is broadening its efforts to include the use of social infrastructure in ways that go beyond the boundaries of an automobile manufacturer.

(1) Probe car traffic information (vehicle location, speed, etc.) is collected from the car navigation systems of SKY project volunteers, and precise traffic information is processed at the Probe information center.

(2) The traffic information processed from this Probe information is provided to the car navigation systems of trial volunteers. This allows a greater amount of road traffic information to be obtained than with the earlier VICS (Vehicle Information and Communications System). Using this traffic information enables drivers to find a faster and smoother route, thereby helping to ease congestion.