XTRONIC CVT with Auxiliary Transmission

| 2010 | Adopted for Nissan March |

|---|---|

| 2010 | Announced at the Advanced Technology Briefing |

Efficient and compact CVT technology for small vehicles

CVT (Continuously Variable Transmission) is a system with seamless, “stepless” gear transmission. Early on Nissan understood the merits of CVT, low-fuel consumption and seamless acceleration, developing and adopting the technology for its vehicles.

The XTRONIC CVT with Auxiliary Transmission is a new form of CVT for small vehicles, realizing further enhanced fuel efficiency and responsive drive.

Technology Functionality

CVT is a “stepless” transmission system. As opposed to MT (Manual Transmission) or AT (Automatic Transmission), CVT can automatically select the most suitable transmission gear ratio without any steps. Vehicles with CVT can run on the most efficient (i.e. with the best fuel combustion) engine rpm for regular velocity. The technology delivers seamless performance without shift changes when accelerating and decelerating.

Further, by adopting an auxiliary transmission it becomes compact enough to be included with small-size vehicles, while also expanding the low-to-high gear ratio range. Simultaneously, through transmission gear ratio control that matches the way you drive, it improves the response when starting off and moving at low speeds, and also delivering low engine rpm when traveling at high speeds.

Technology Configuration

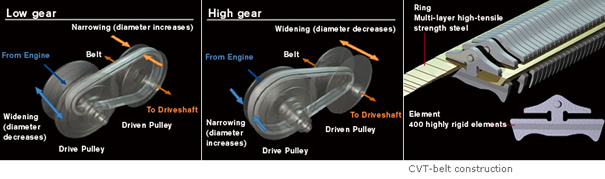

CVT adjusts the width of two pulleys and changes the arc radius of the steel belt running between them in order to control the transmission gear ratio.

In the illustration above, the arc radius of the belt for the engine shaft pulley gets narrower. This is ideal for driving at slow speeds, when gears on MT or AT vehicles are lower (for example, first or second gear).

On the other hand, when in high gear, the belt on the drive pulley gets wider. This is suitable for high-speeds when the gear is high, such as in fifth or sixth.

The steel belt is serving here to bridge the two pulleys and change the diameter.

If the gear ratio at low gear is lowered even more, acceleration improves. This is the same as how starting in first gear has more power than starting in second. As well as when moving off, vehicle response improves at lower speed.

On the other hand, when the gear ratio runs at a higher gear, the engine rotation decreases even at high speed, meaning there is better fuel combustion and less noise. This is the same logic as how when driving on a highway in fifth gear the engine rotates less than fourth gear.

Accordingly, in addition to the acceleration, the fuel combustion and engine noise levels can be improved by making the low and high gear ratio range (known as transmission gear ratio range) larger.

In previous CVT systems, it was necessary to increase the size of the pulleys to expand the range of the transmission gear ratio, making it hard to implement in a small vehicle due to the layout limitations.

The XTRONIC CVT with Auxiliary Transmission adds to the transmission function utilizing the pulley and belt, and by adopting an auxiliary two-speed transmission, the transmission range has been expanded while keeping the pulleys small in size.

Friction is reduced by up to 30% by expanding the range of torque computer lockup, adopting a high-efficiency oil pump, and reduced oil agitating resistance. This all contributes towards improved fuel economy.

Main Features of XTRONIC CVT

Transmission gear ratio range 7.3 (Standard model: 6.0)

Fuel economy +10%* (target value)

Friction reduction up to 30%*

Weight reduction -13%*

Size reduction -10%*

- *Comparison with other CVT in similar class Nissan vehicles (Nissan research)