Air Quality & Water

Nissan is committed to achieving zero water risk by enhancing water risk management and zero impact on air quality by minimizing emissions from our vehicles and corporate activities.

NGP2030 Activities

Water

- Enhance water risk management at manufacturing sites

- Reduce water usage at manufacturing sites

- Manage wastewater quality at manufacturing sites

Air Quality

- Enhance management of vehicle emissions, including non-tailpipe emissions

- Manage volatile organic compound (VOC) at manufacturing sites

- Manage in-cabin air quality

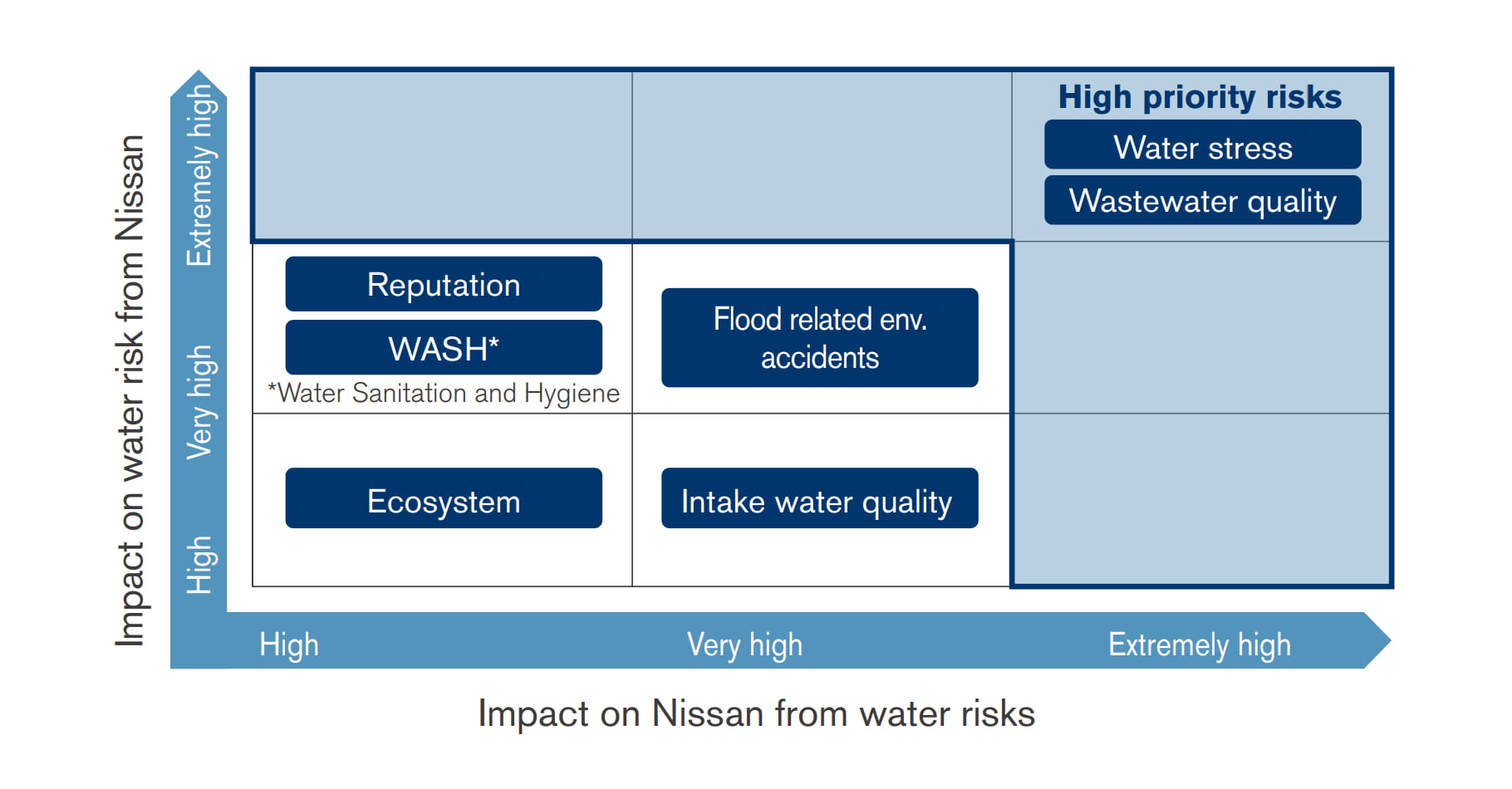

Water plays a crucial role in Nissan’s operations, from painting and cleaning to cooling. Recognizing "water stress (water shortage)" and "wastewater quality" as key risks, we are working to reduce water use and regularly assess potential water-related challenges to stay ahead of these issues.

Materiality of Water Risks

Water usage management

Water stress analysis

Water stress is assessed at all global manufacturing sites. The Aqueduct Water Risk Atlas from the World Research Institute is used to evaluate water stress, and production volumes are considered to assess business impacts. NGP2030 aims to reduce water usage, particularly at manufacturing sites with high risk related water. We also continue efforts to reduce water usage continue at all sites.

Water stress analysis

Water stress is assessed at all global manufacturing sites. The Aqueduct Water Risk Atlas from the World Research Institute is used to evaluate water stress, and production volumes are considered to assess business impacts. NGP2030 aims to reduce water usage, particularly at manufacturing sites with high risk related water. We also continue efforts to reduce water usage continue at all sites.

Waste water quality management

Wastewater quality impacts water availability, particularly in regions with limited water resources. At Nissan's manufacturing sites, wastewater treatment is implemented according to stricter standards than local regulations to ensure compliance with wastewater quality management laws.

Waste water quality management

Wastewater quality impacts water availability, particularly in regions with limited water resources. At Nissan's manufacturing sites, wastewater treatment is implemented according to stricter standards than local regulations to ensure compliance with wastewater quality management laws.

Nissan is dedicated to improving air quality by reducing emissions not only from our vehicles but also from in-cabin environments and manufacturing processes. We are expanding our commitment to air quality by aligning with global regulatory trends and taking responsibility for reducing all emissions from our operations and products.

Reduction of emissions from vehicles

Managing and improving out-cabin environments

Nissan plans to reduce emissions from its vehicles by:

・ Promoting Zero-emissions vehicles (EVs)

・ Enhancing internal combustion engines

・ Reducing non-tailpipe emissions and particulates

Managing and improving in-cabin environments

To reduce emissions within vehicles, Nissan is engaged in the following activities:

・ Complying with Nissan’s VOC* standards stricter than those of various countries

・ Research and development for improving in-cabin environments

*VOC: Volatile Organic Compounds

Managing and improving out-cabin environments

Nissan plans to reduce emissions from its vehicles by:

・ Promoting Zero-emissions vehicles (EVs)

・ Enhancing internal combustion engines

・ Reducing non-tailpipe emissions and particulates

Managing and improving in-cabin environments

To reduce emissions within vehicles, Nissan is engaged in the following activities:

・ Complying with Nissan’s VOC* standards stricter than those of various countries

・ Research and development for improving in-cabin environments

*VOC: Volatile Organic Compounds

Reduction of emissions from manufacturing activities

Vehicle manufacturing plants typically emit nitrogen oxides (NOx), sulfur oxides (SOx), and volatile organic compounds (VOCs). Nissan has consistently implemented stringent measures to mitigate the emission of these substances.

Reduction of emissions from manufacturing activities

Vehicle manufacturing plants typically emit nitrogen oxides (NOx), sulfur oxides (SOx), and volatile organic compounds (VOCs). Nissan has consistently implemented stringent measures to mitigate the emission of these substances.

Initiatives

For more details, please view the Sustainability data book.