The COVID-19 pandemic has upended daily life across the globe and challenged everyone to do their part to help save lives. For some of us, it may be things as basic as washing our hands. For others, like health care workers, it means risking infection every day while fighting on the front lines.

For Nissan, responding to this unprecedented crisis has first and foremost meant taking measures to protect employees, customers, and all members of the global Nissan family by changing the ways the company does business on a daily basis.

At the same time, companies around the world have also been called upon to assist patients, health care workers and governments in a variety of ways by using their specialized resources. In response to this challenge, Nissan has mobilized its capabilities in the areas of manufacturing and transportation – along with the company’s greatest resource: the many employees who have contributed their time, energy and skills.

Here are some examples from around the world:

3D printers and packing sheets

From its home country of Japan to factories overseas, Nissan has used its manufacturing capabilities to produce face shields, medical gowns, ventilators, masks and machines for mask making, and delivered them to medical institutions and local governments.

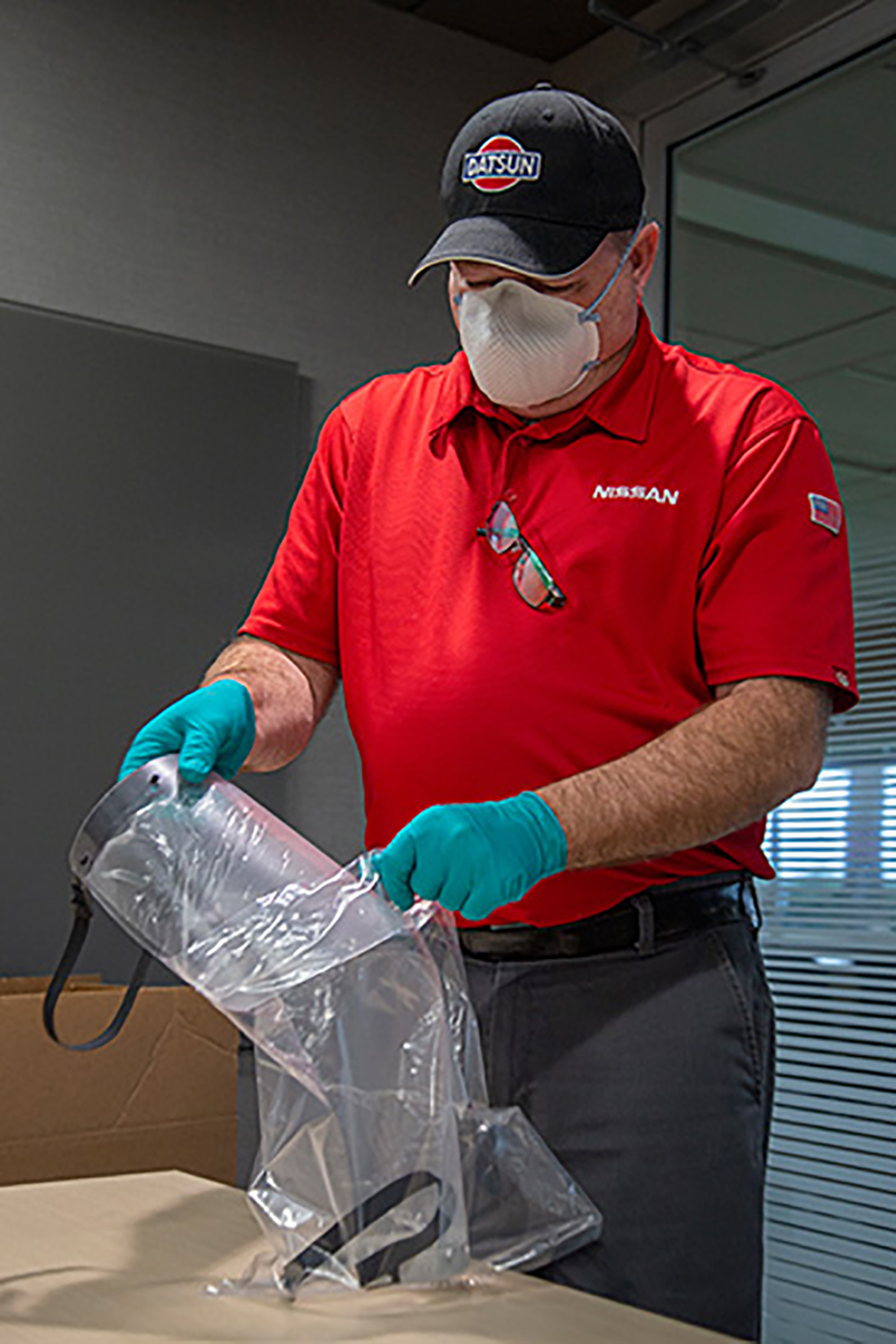

Using 3D printing – a tool Nissan normally applies in development design and prototyping – the company has made protective face shields for health care workers at R&D facilities and factories in Japan, the U.S., the U.K., Spain, South Africa and Mexico. Many employees offered their skills and experience, and in the U.K., employees volunteered to package and dispatch the face shields. Affiliates Nissan Shatai and Nissan Motorsports International (NISMO) have also launched similar projects.

“We knew we had resources, knowledge and a motivated workforce that wanted to help fight the COVID-19 pandemic any way we could,” said Tim Fallon, director of trim and chassis operations at the Smyrna Vehicle Assembly Plant in Tennessee. “It’s very humbling to be able to give back to the community and to the doctors and nurses who are fighting this pandemic.”

Nissan employees have also come up with novel approaches to meet the surging demand for medical gowns – using packing sheets to make the gowns and developing a special trim jig tool to boost operating efficiency. The gown design was developed through five prototypes, based on doctors’ advice and requests from the government in Kanagawa, Japan, where Nissan is based.

Nissan North America employees create face shields for those in need

Prepping face shields for pack-up and delivery

Working with partners

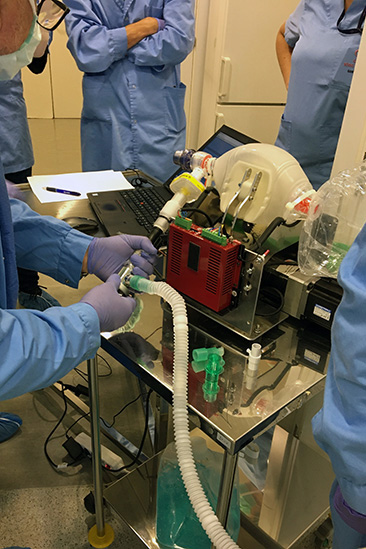

At Nissan’s powertrain plant in Barcelona, Spain, the company has cooperated with affiliated engineering firms and medical institutions to make ventilators for treating COVID-19 patients. In Brazil, engineers at the Resende Plant have helped repair ventilators through a partnership with other carmakers.

Nissan workers in Brazil repairing ventilators

Doctors in Spain test out ventilators produced by Nissan

In China, Nissan and its partner Dongfeng Motor set up a production line to build mask-making machines. This involved working with materials that aren’t commonly used in car manufacturing, but the project team met the challenge and got the line up and running within a short time.

Plant workers in China working on mask-manufacturing machines

Worker puts finishing touches on the completed mask-manufacturing machines

In Japan, Nissan has joined other companies in signing the IP Open Access Declaration Against COVID-19, agreeing not to seek compensation or assert any patents or copyright in connection with activities to prevent the spread of COVID-19. The declaration aims to promote the fastest and best ways to combat the outbreak without spending time and resources on issues such as intellectual property rights or licensing.

Nissan employees in Japan cutting out the pattern for a medical gown

Nissan employee try on the finished medical gown

Maintaining mobility

Amid lockdowns, movement restrictions and social distancing measures, finding ways to safely transport health care workers, patients and medical supplies has been another big challenge. As a company specializing in vehicles and mobility solutions, Nissan has worked with governments, local communities, medical institutions and NGOs in many countries to address it.

In the U.K., Nissan launched an initiative to provide health care workers with free vehicles, titled “Keeping Heroes Moving.”

“Our health care workers are under immense pressure,” said Andrew Humberstone, managing director of Nissan Motor GB. “Nissan wanted to offer support in enabling their journeys to be trouble-free and more convenient.”

In Thailand, partnering with the Red Cross, Nissan has started a caravan project to transport medical supplies and food to local communities, with Nissan employees participating as drivers. In South Africa, the company has joined forces with a local university to support the government’s COVID-19 screening program, using Nissan vehicles to transport the project’s medical team. And in Japan, Nissan is planning to provide vehicles for transporting some COVID-19 patients.

Nissan vehicles used by the Red Cross in Thailand

Nissan staff in South Africa supporting the nation’s COVID-19 screening program

Nissan mobilizes vehicles to help transport medical personnel, medicine and food supplies

As the pandemic evolves, Nissan is continuing to work with authorities and partners and adjusting its approach based on local conditions and government directives. The company and its employees continue to be inspired by the dedication of everyone involved in the effort and will continue to devote its energy to the fight against COVID-19.

For more information about Nissan’s response to COVID-19, please click here.