HCCI (Homogeneous-Charge Compression Ignition)

HCCI is the ultimate combustion method for achieving both CO2 reduction and clean exhaust using auto-ignition of gasoline, as in a diesel engine. Nissan is developing this technology for commercial use.

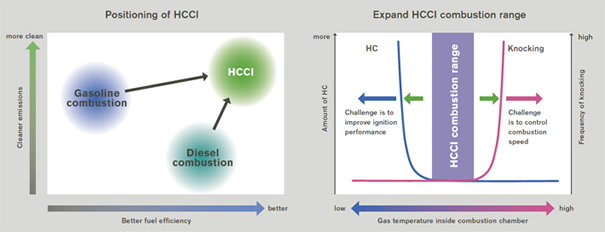

Characteristics of HCCI

The system features lower-temperature combustion compared to ordinary gasoline engines, resulting in nearly no NOx emissions. It offers the highest potential heat efficiency among internal-combustion engine systems, leading to projections of major cuts in CO2 emissions. Current HCCI technology allows only a limited range of stable combustion, and expanding that is the challenge ahead.

Technology for Measuring Gas Temperature inside Combustion Chamber

To accurately measure the gas temperature inside the combustion chamber, which is key to HCCI combustion, Nissan and Stanford University jointly developed technology to measure the real-time gas temperature inside the engine. This technology is being utilized for the development of HCCI.

3D HCCI Simulation Technology

As the ignition mechanism for HCCI combustion does not depend on spark plugs, it is necessary to control the auto-ignition timing and combustion duration. Nissan has newly developed technology to accurately simulate HCCI three-dimensionally.

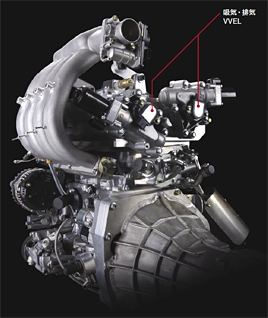

Utilization of VVEL

To control the gas temperature inside the combustion chamber, it is necessary to change the amount of residual exhaust gas accordingly to driving conditions. Nissan uses VVEL, which allows free-control of the valve timing and lift, for both intake and exhaust valves, to control temperature by effectively using internal EGR.

RELATED TECHNOLOGY

Three-dimensional HCCI simulation

To build the ultimate HCCI engine for low fuel consumption and emissions, Nissan has developed pioneering visual simulation technology that models the engine in minute detail in three dimensions. This greatly assists in precise understanding of the chemical reactions in the combustion process, leading to more efficient engine development.