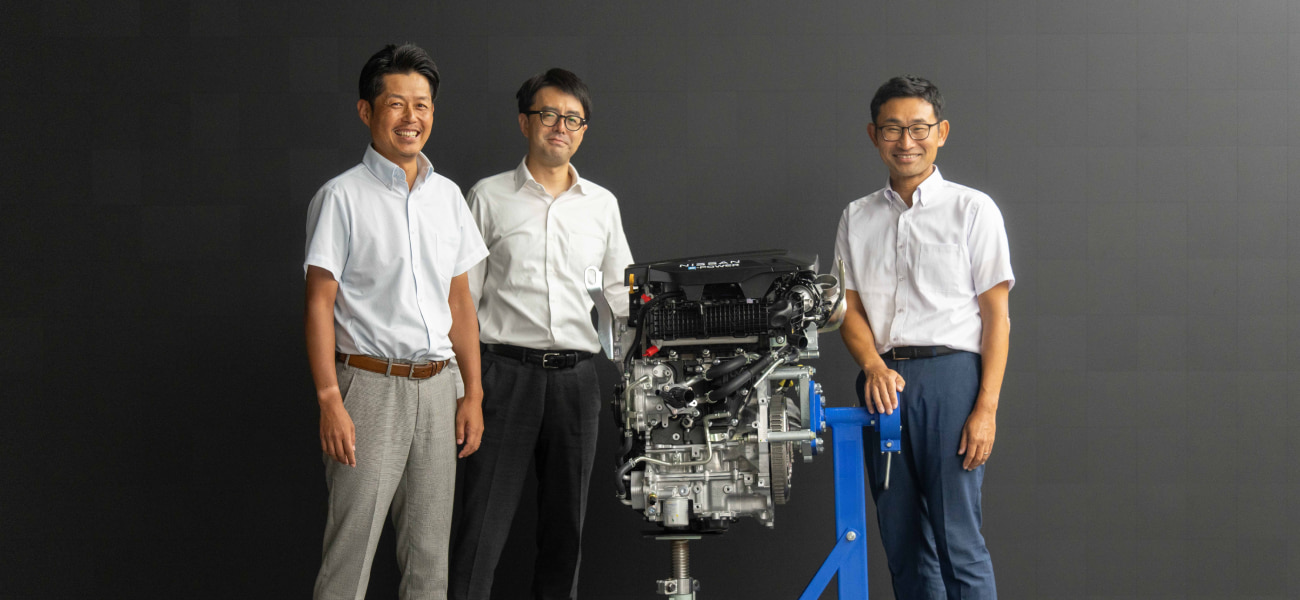

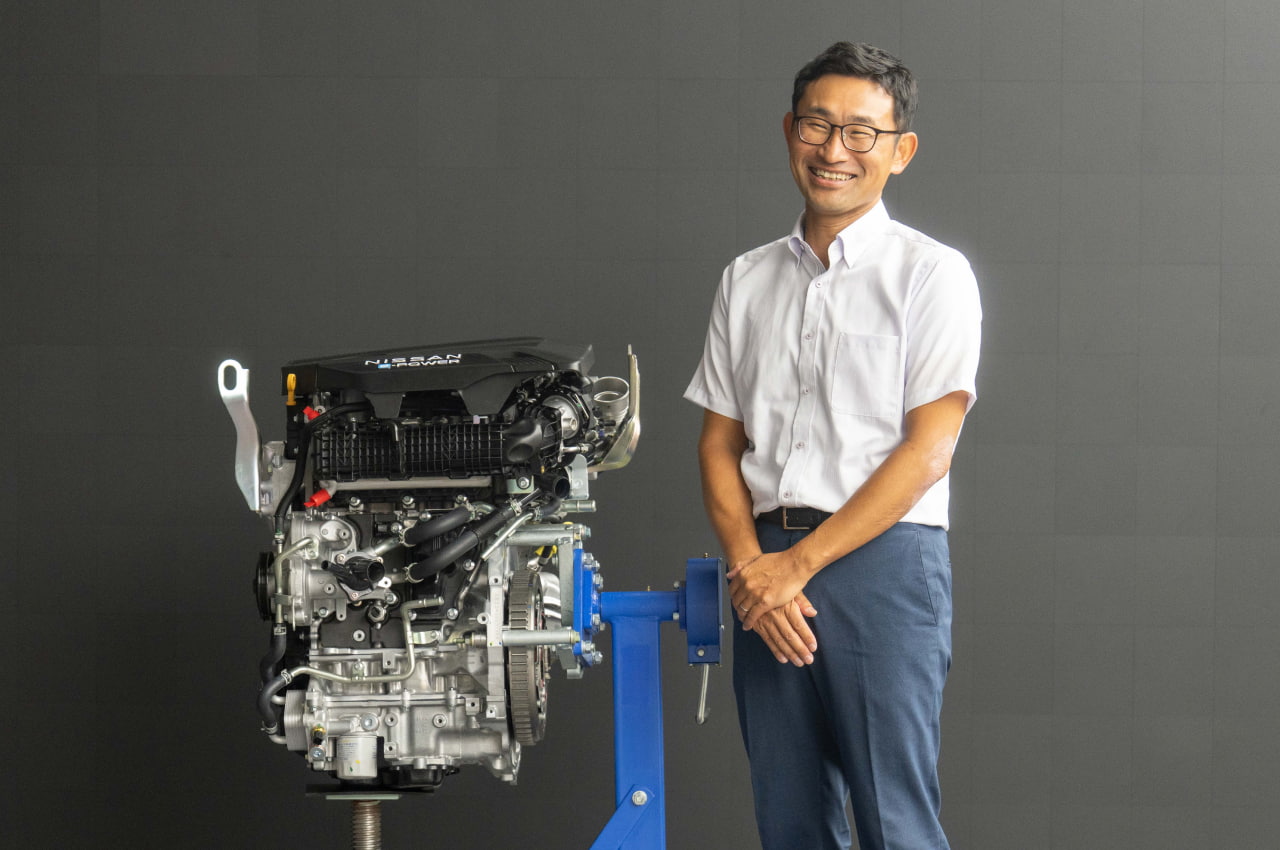

Nissan's third-generation e-POWER system launches in the Qashqai in Europe this month, delivering enhanced efficiency, lower emissions, and a quieter drive. Norihiko Tagishi, Akihiro Shikata and Naohiro Yoshida of Nissan's powertrain team in Japan, who developed the breakthrough new engine at the heart of the system, divulge details of the challenges they overcame and explain how it works.

Reimagining Nissan's third-generation hybrid powertrain

e-POWER is Nissan's hybrid system, a unique electrified powertrain that combines a compact gasoline engine and an electric motor. The gasoline engine is used solely to generate electricity which is distributed directly to the electric motor to drive the wheels, as well as to charge the battery if needed. The powertrain provides the smooth, effortless acceleration and refinement of an EV with the everyday convenience of traditional combustion vehicle ownership.

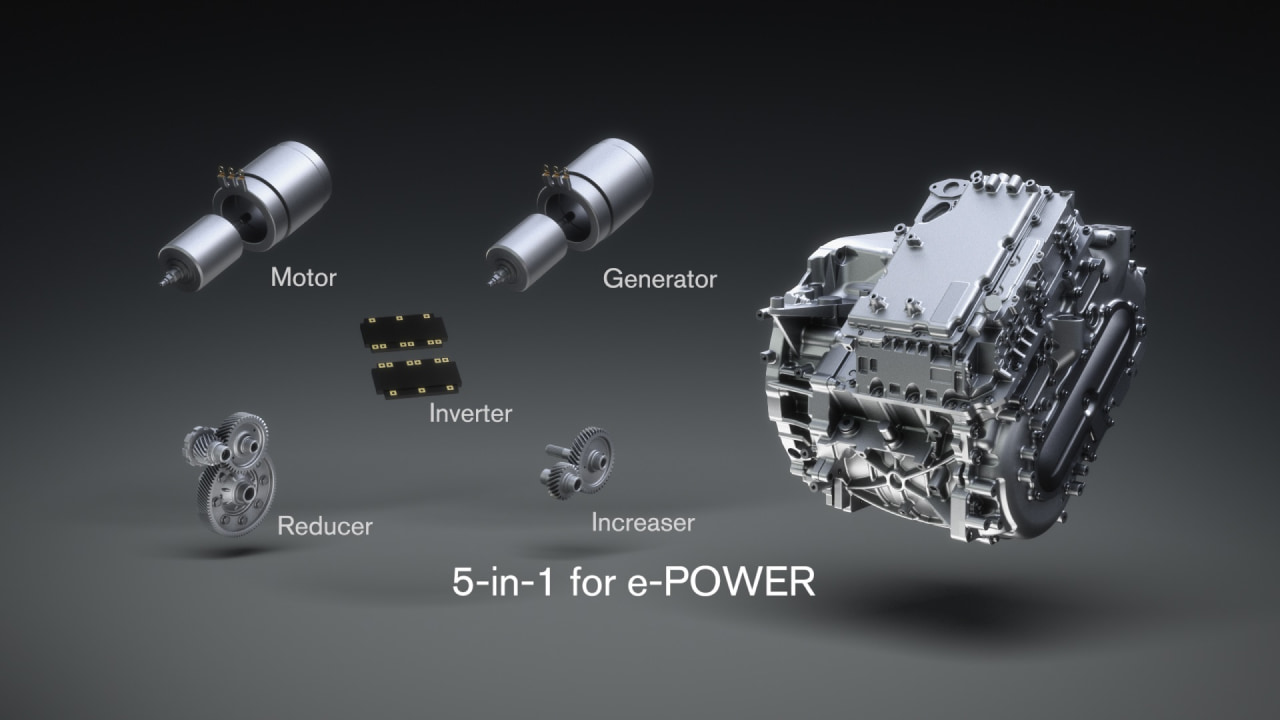

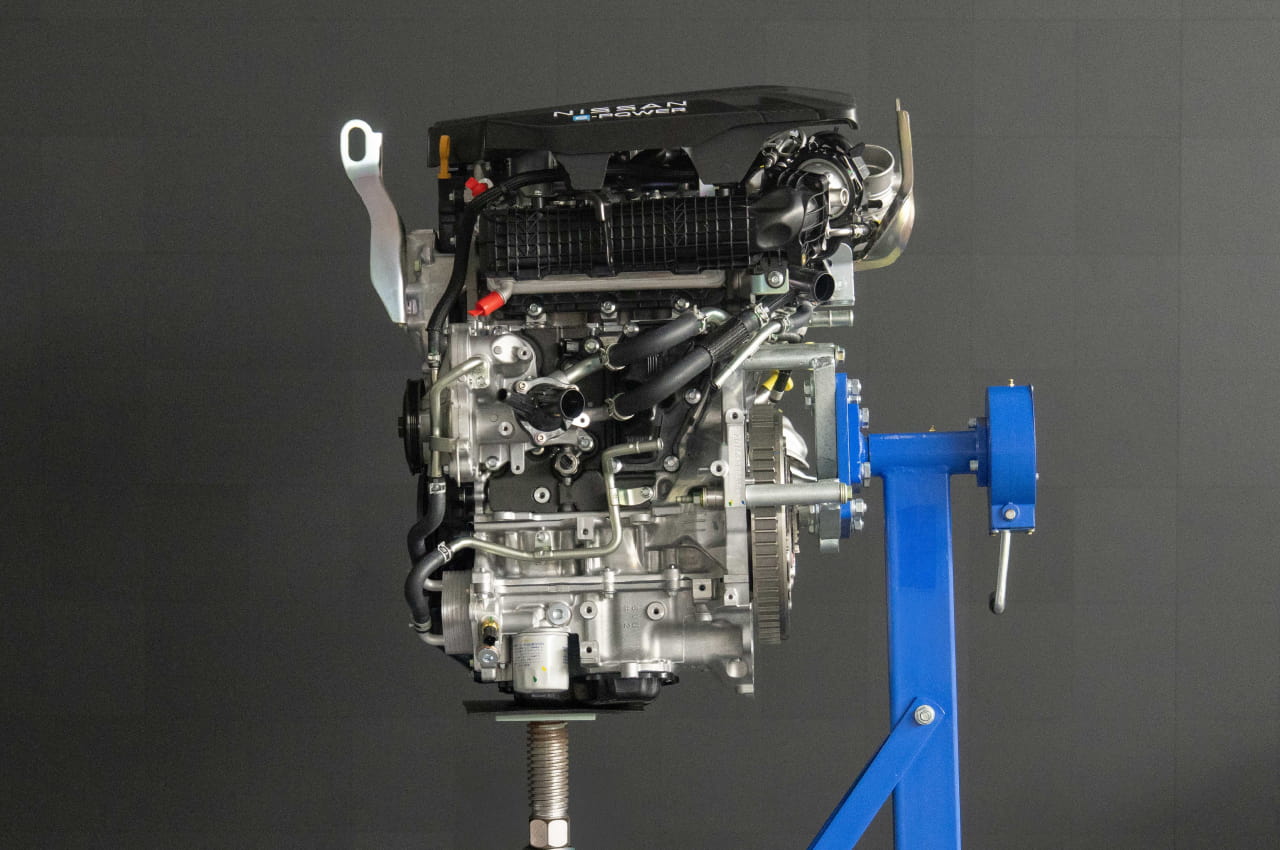

In addition to a new 5-in-1 design, which integrates core components of the electric powertrain into a more rigid, lighter unit for enhanced refinement, the third-generation e-POWER system adopts a breakthrough new 1.5-liter 3-cylinder turbocharged gasoline engine codenamed ZR15DDTe.

Dedicated to a single purpose

Unlike the engines employed on previous generations of e-POWER, the new engine was designed from the very beginning as a dedicated generator - exclusively providing electricity for e-POWER vehicles.

Norihiko Tagishi, Senior Manager of e-POWER project management group, said "When we started in 2021, we took an unconventional approach, designing the engine concept differently from traditional engines. As we incorporated many new features, we faced unprecedented technical challenges at every stage of development. Nevertheless, by uniting the development and production teams and refusing to give up, we were able to overcome these obstacles."

While a conventional internal combustion engine in a typical vehicle needs to operate efficiently across a wide range of speeds (RPMs) and loads, the engine in e-POWER vehicles is dedicated solely to generating electricity. This allows Nissan's engineers to tune it precisely to operate within the most efficient range.

Aiming for higher thermal efficiency

Thermal efficiency is a measure of how much energy from the fuel is converted into useful mechanical output (power) with the rest lost as heat. The greater the thermal efficiency an engine offers, the further it can drive on the same tank of gasoline. In the case of e-POWER, improving thermal efficiency leads to more efficient power generation.

Akihiro Shikata, Senior Manager of powertrain unit performance calibration development group, said "We began development by redefining the kind of engine required for a dedicated power generation unit. By relaxing the demands for engine responsiveness, we were able to design it to achieve optimal performance focused on the point of highest thermal efficiency and peak output."

The innovative new engine applied to Nissan's third-generation e-POWER, offers an impressive thermal efficiency of 42%.

Mass production adoption of the STARC Concept

A key breakthrough to achieve high thermal efficiency is the adoption of Nissan's proprietary Strong Tumble & Appropriately stretched Robust ignition Channel concept.

Known as STARC for short, it creates a tumble effect of the fuel and air mixture as it is injected into the cylinder, maintaining this until ignition to ensure efficient combustion. This generates a strong tumble flow (vertical vortex) inside the combustion chamber and stabilizes the spark discharge channel, leading to better combustion conditions. Even with the large-scale use of EGR (exhaust gas recirculation), which helps improve thermal efficiency, stable combustion is maintained. To produce the optimal tumble flow, Nissan's engineers thoroughly reviewed and optimized various components, including the intake port, valve angle, pent roof shape, and piston crown surface, to create the ideal combustion chamber.

Balancing high thermal efficiency and engine power

To improve both thermal efficiency and engine output, the team adopted numerous additional technologies. They used a dedicated turbocharger larger than what is typically applied to a 1.5-liter engine, to reduce pump losses. Coupled with innovative valve timing adjustments and measures to avoid knocking, they were able to set an ideal ignition timing even with a high compression ratio. As a result, they achieved a high compression ratio of 13:1, which is rare for a turbocharged engine, successfully balancing high thermal efficiency with high power output.

Throughout the development, the team faced significant challenges not only in achieving high thermal efficiency but also in maintaining high output. Under conditions of high compression ratio and high boost pressure, abnormal combustion (pre-ignition), where the fuel ignites before the spark, tends to occur more easily, potentially damaging the engine. However, through meticulous control technology, they succeeded in preventing this.

Additionally, large turbochargers typically feature ‘lag' which causes a delay in engine torque response, however by leveraging the energy management features of e-POWER, the team ensured that vehicle acceleration was unaffected, overcoming this issue as well.

Enhancing efficiency and refinement

In the case Qashqai, the improvement in thermal efficiency at the higher torque ranges of the engine, allows the vehicle to maintain a constant engine speed even at higher driving speeds. This change, along with the more rigid 5-in-1 integrated structure, contributes to lower overall noise levels and more refined, stress-free drive experience. The Qashqai equipped with this powertrain has achieved up to 16% improvement in fuel efficiency under real-world driving conditions, and 14% improvement on highways, compared to previous models.

Pairing technology from other industries with Nissan's unique approach

A key element of developing the new engine was delivering smooth airflow from the intake port into the combustion chamber, resulting in a strong tumble flow. In conventional engines, the design of the intake port is constrained by the necessity for press-fitted, sintered valve seats, which limit the ability to optimize port shape for ideal tumble flow.

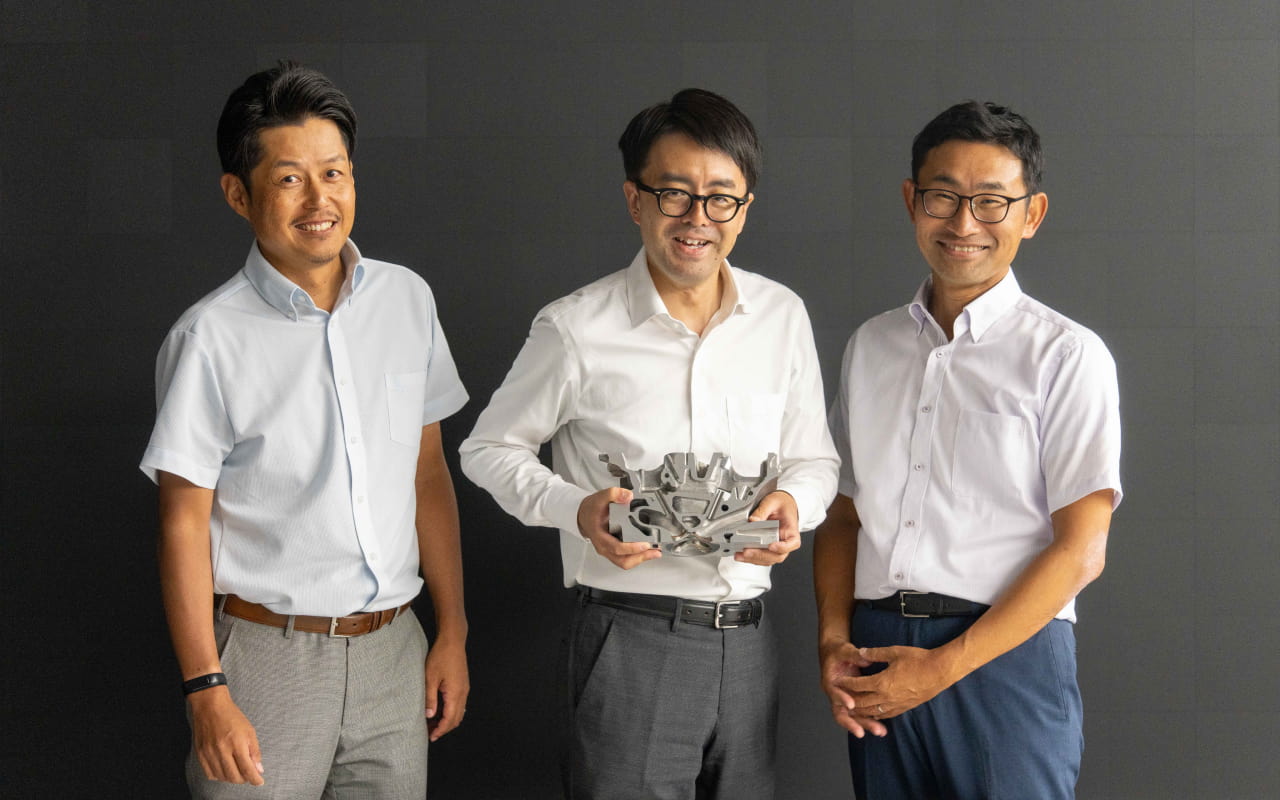

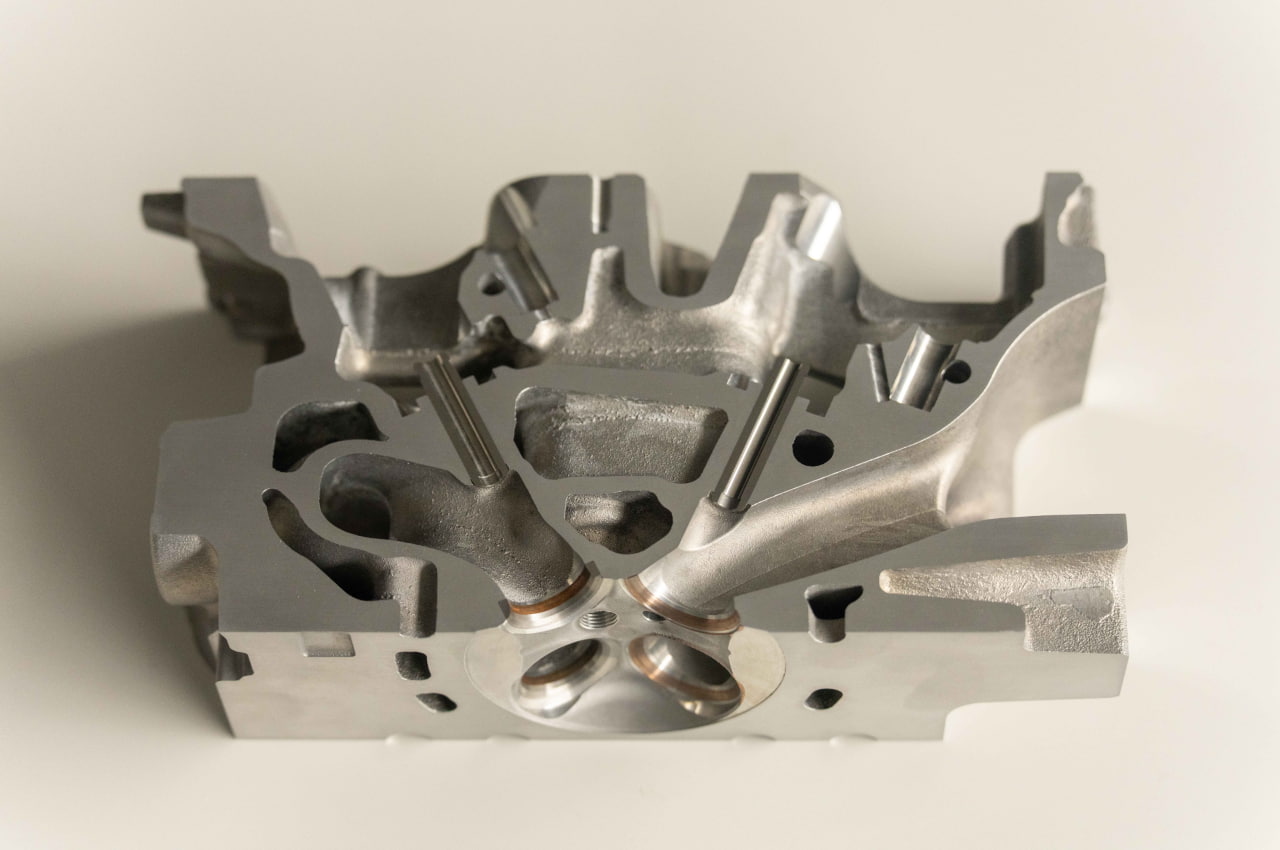

Members of the team hold a cross-section of the cylinder head from the ZR15DDTe engine

Nissan engineers explored numerous options in long term technology development to address this challenge and determined that ‘cold spray technology,' which has been used in the aerospace, energy, heavy equipment, oil and gas, and other manufacturing industries, provided an advantage in terms of reliability and quality.

The process incorporates a specially developed alloy, in-house nozzles inspired by polishing techniques built up in forging mold production, resulting in a world-first application within an automotive engine.

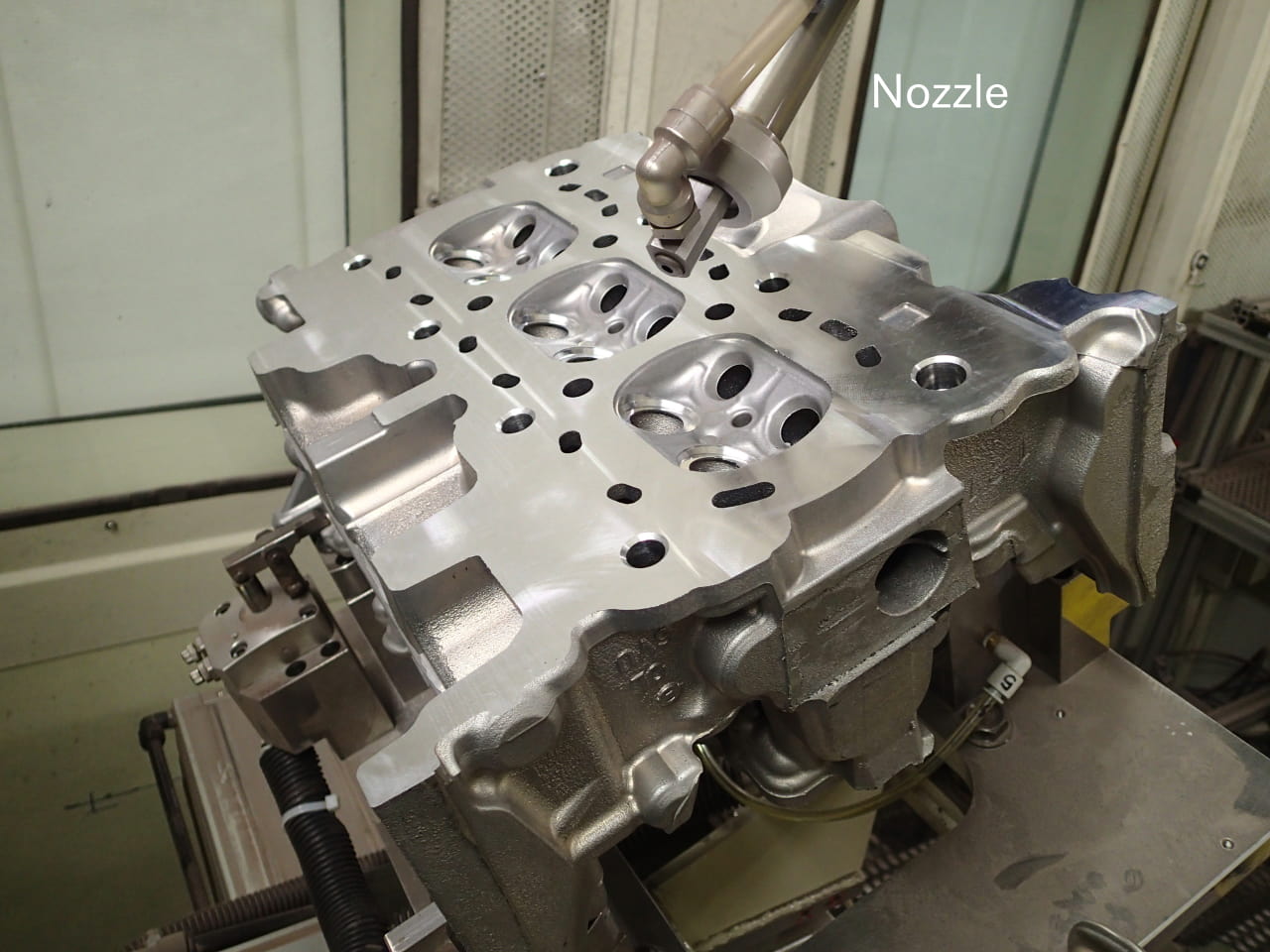

The newly developed nozzle applying the cold spray valve seat to the ZR15DDTe engine

Naohiro Yoshida, Chief Powertrain Engineer said, "From the beginning, we knew it would be difficult; however the team enjoys a challenge and knew customers would appreciate the benefits of our e-POWER technology even more when we succeeded. In the end, we overcame it with the cooperation of our three Monozukuri divisions (R&D, Production, Purchasing), relevant departments and our partner companies."

By overcoming numerous complex technical challenges, the ZR15DDTe engine has achieved high performance as a dedicated power generation engine.

Future expansion

After the Qashqai, customers in the U.S. and Canada, as well as Japan, will be the next to experience Nissan's new, third-generation e-POWER technology, which will gradually expand to more models and regions.

New e-POWER is scheduled to arrive in FY26 in the next-generation Rogue for the U.S. and Canada. It will also power the next-generation Nissan Elgrand, a large minivan for Japan, with other markets and regions to follow.

The pursuit of efficiency and power continues

This new engine represents a major leap forward in the team's journey to create the ultimate e-POWER dedicated engine. Engineers at Nissan's R&D center in Atsugi, Japan, continue to work toward an ambitious long-term goal of achieving higher thermal efficiency in e-POWER dedicated engines, as well as applying technologies such as STARC across a wide range of Nissan engines.

It's all part of Nissan's ongoing effort to improve fuel economy, extend range, and reduce emissions. These initiatives support our goal of creating more sustainable mobility and delivering ever-higher satisfaction for customers around the world.