Third generation e-POWER

e-POWER is Nissan's unique electric-drive hybrid powertrain that integrates an electric motor with a gasoline engine. Since the system is 100% driven by a high-output motor, drivers can enjoy an EV-like experience with the peace of mind of an onboard gasoline engine for generating energy for the battery.

e-POWER history

Key points of evolution

The third-generation e-POWER system combines a purpose-built engine designed specifically for e-POWER applications. With the ground-up approach of the purpose-built engine, power generation from the engine is further optimized from the previous generation, including activation timing independent of driving conditions and powerband.

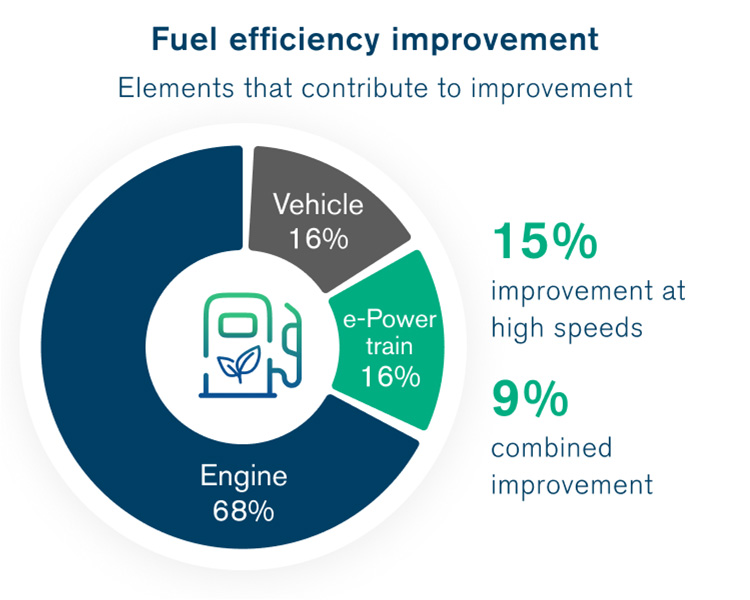

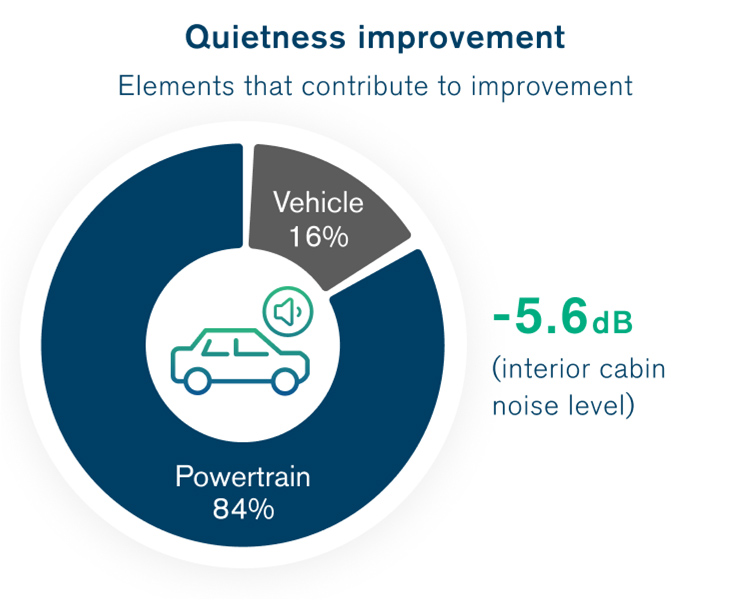

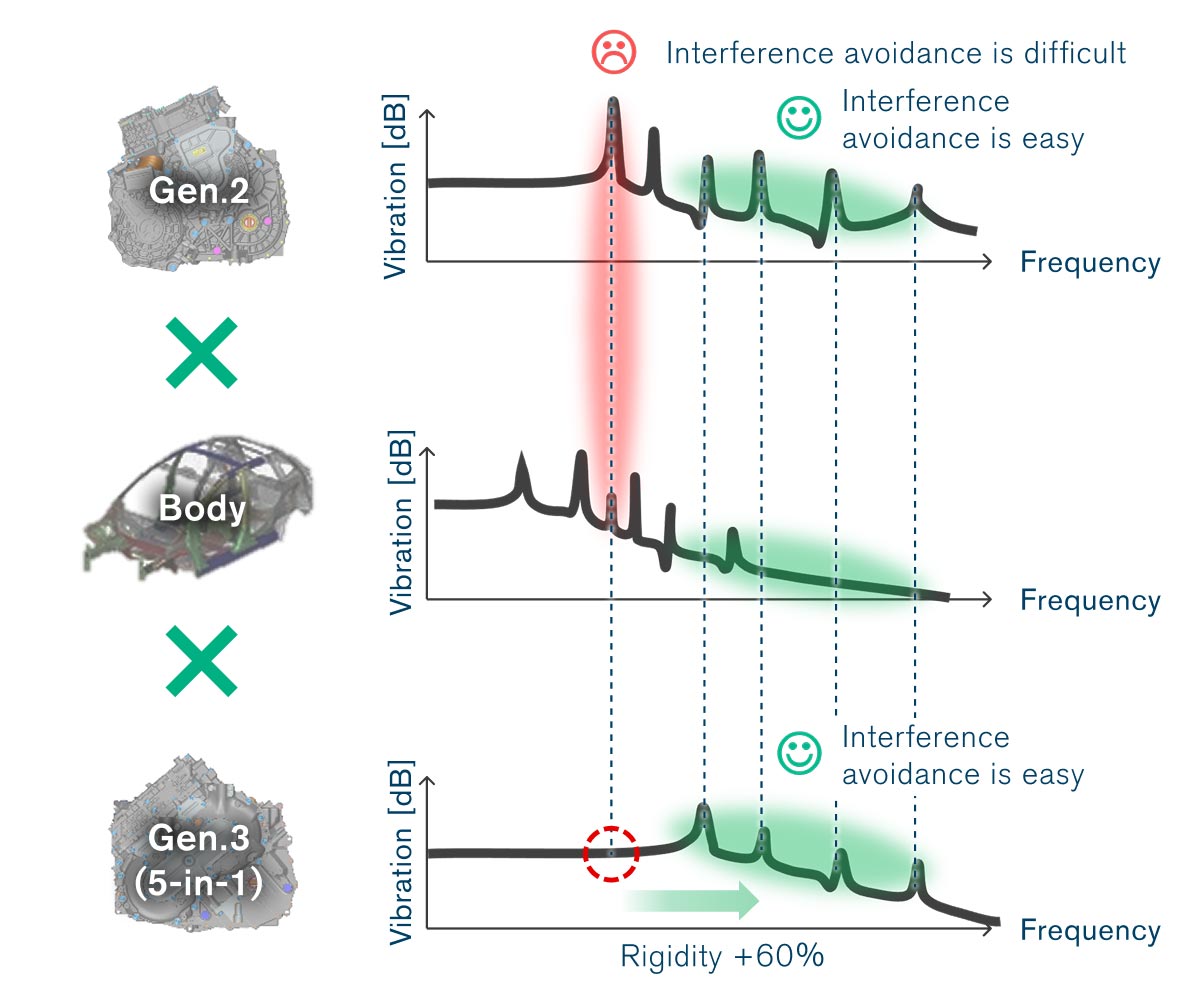

The 3rd-gen's new modular approach, called “5-in-1”, integrates five major components to enhance performance, significantly improving fuel efficiency and quietness.

Compared to 2nd generation e-POWER (Qashqai)

5-in-1 electric unit

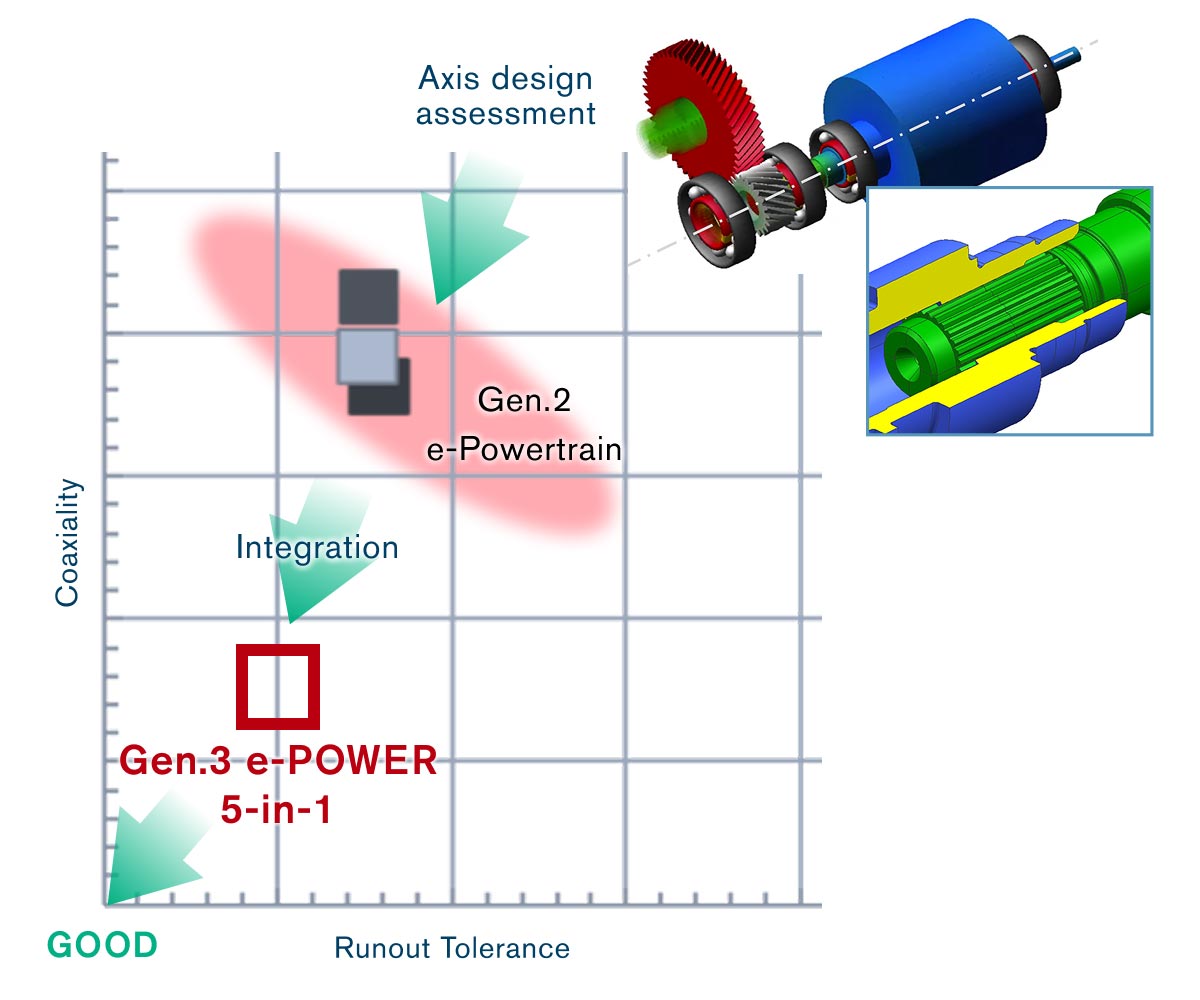

A 5-in-1 modular approach optimizes the packaging of the motor, reducer, inverter, increaser and generator. This approach achieves a high level of efficiency by increasing current flow for greater output and mitigates energy loss.

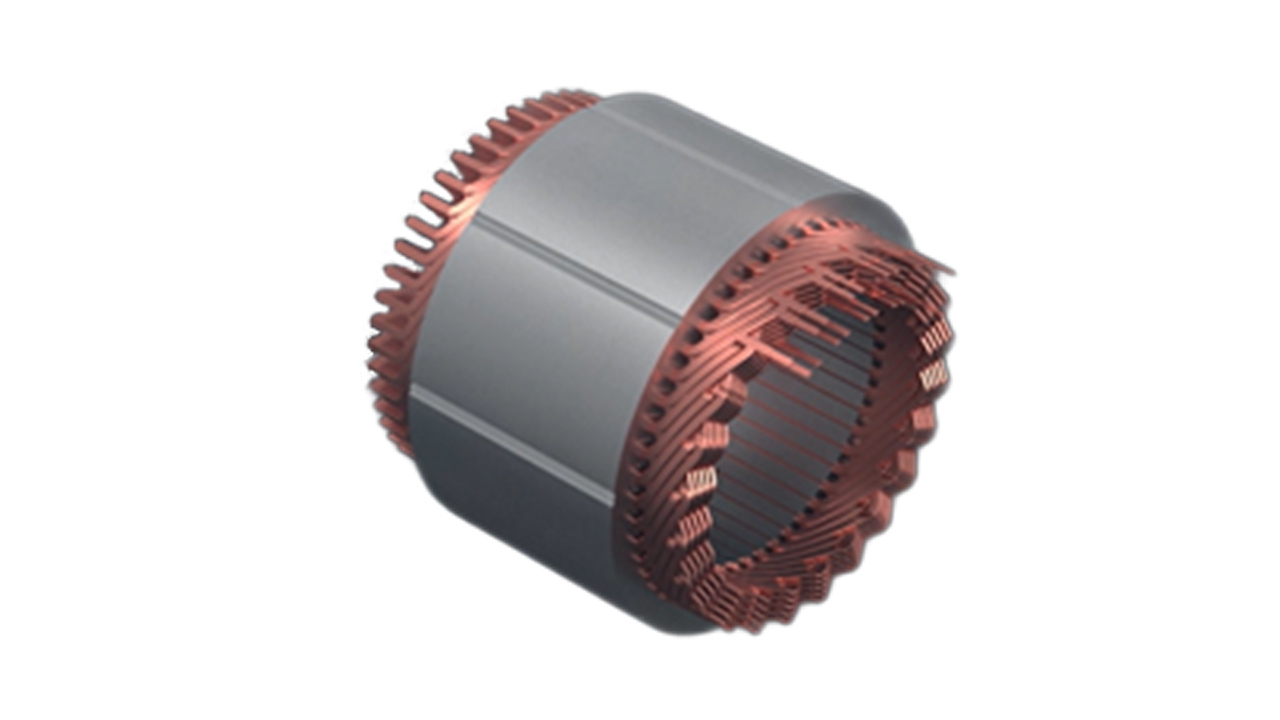

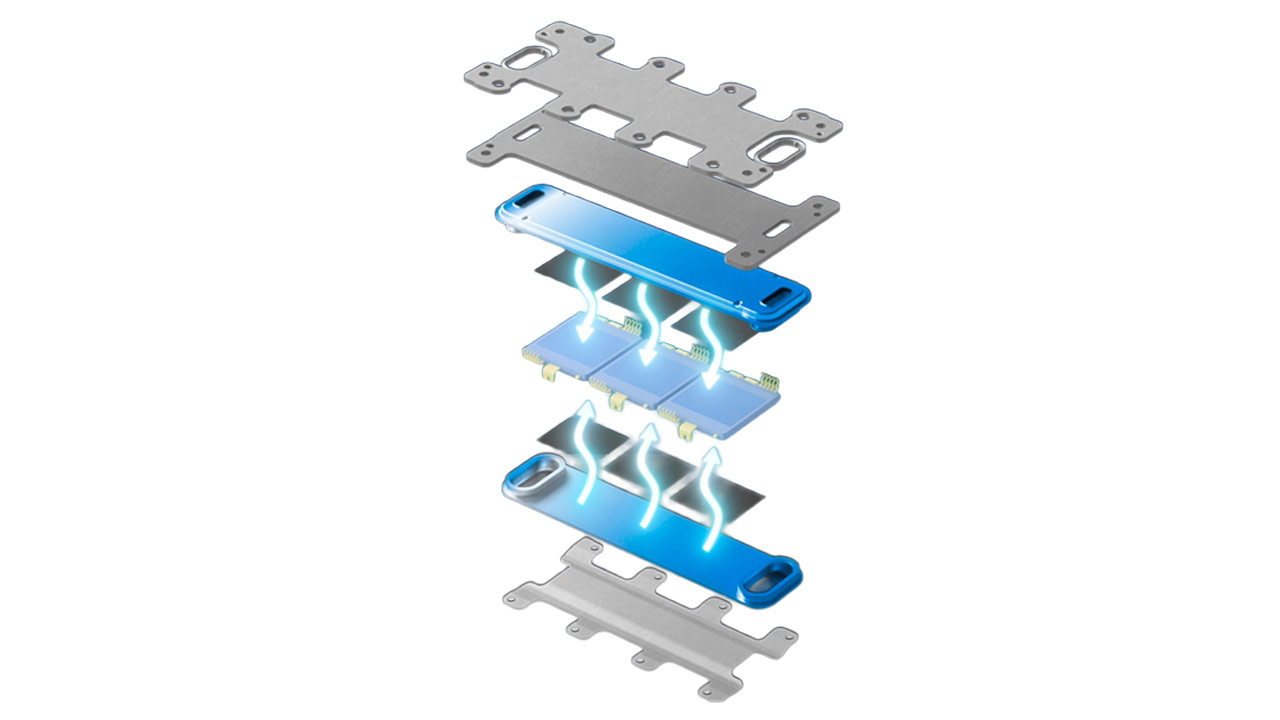

To improve acceleration performance and power consumption, engineers focused on increasing the amount of electrical current to increase output, suppress losses and enhance efficiency. A flat wire coil with a high occupancy ratio was adopted to allow a large amount of electrical current to flow within the motor's compact design. The inverter has a power module with a double-sided cooling structure to improve efficiency, especially in the high-speed range.

Motor flat wire

Inverter double-sided cooling

Improving rigidity through integration avoided interference between the resonance points of the vehicle body to further enhance the system's quietness. This also enabled high-precision assembly, reducing runout tolerances of rotating shafts such as motors and gears, thereby suppressing vibration.

By sharing the 3-in-1 EV powertrain and its components, we not only contribute to reducing the number of parts and production investment but also leverage the technologies and expertise of both EV and e-POWER to efficiently drive the development of further optimized electrified powertrains.

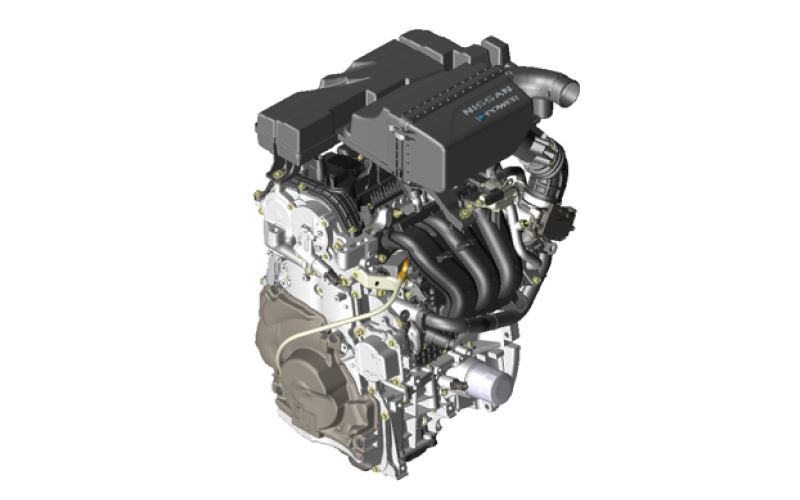

Purpose-built engines for power generation

There are two types of power-generation-focused engines available.

By leveraging a purpose-built onboard engine for power generation, Nissan engineers have achieved a highly efficient powertrain design that significantly improves fuel economy over previous e-POWER applications. A contributor of this is an engine that can maintain a stable combustion cycle.

Purpose-built engine

Purpose-built engine with turbo

In general, to improve engine efficiency, it is important to increase the compression ratio and raise the EGR*1 ratio, which recirculates and mixes exhaust gas with the air intake system. Since a typical engine operates across a wide RPM range depending on driving conditions, it is difficult to maintain a stable and optimal combustion cycle.

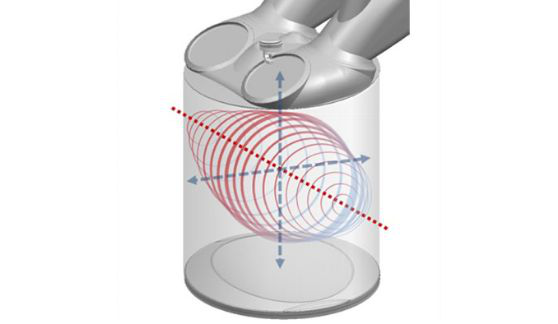

Nissan's purpose-built engines can operate at a constant speed and maintain stable combustion thanks to their long-stroke design that creates a strong in-cylinder flow (tumble flow). This enables combustion stability even with a high compression ratio and high EGR rate.

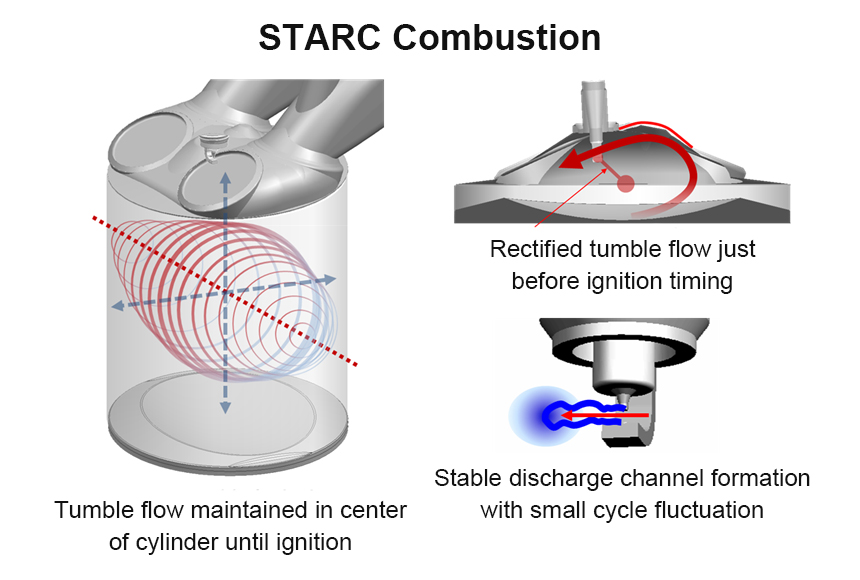

To further improve fuel efficiency and output, one of the purpose-built engine uses Nissan's unique STARC*2 concept paired with a large turbocharger.

The STARC concept is the embodiment of research findings that highlight the importance of controlling airflow toward the spark plug inside the combustion chamber to improve ignition. The concept involves managing airflow so that the discharge channel from the spark plug remains stable, guiding combustion effectively and providing a stable combustion even with a high EGR rate.

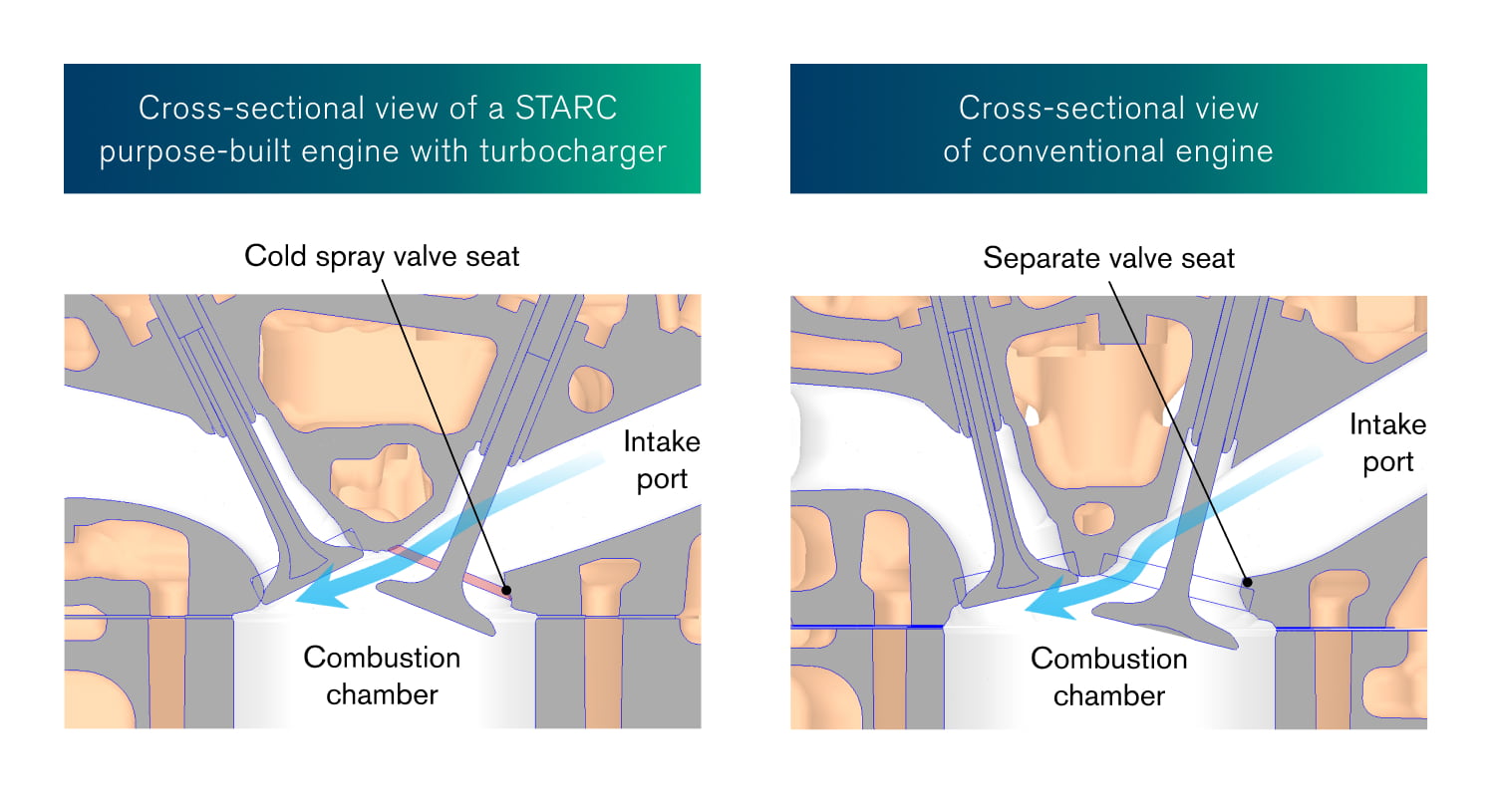

By using cold spray technology to integrate the valve seat into the engine's intake port, the ideal port shape is achieved, allowing air to be forcefully directed into the cylinder with a strong tumble flow. Additionally, the piston crown is precisely shaped to maintain tumble flow during compression, thus ensuring ignition with a strong spark and stable combustion.

The large turbocharger forces a substantial amount of compressed exhaust gas and air into the cylinder, boosting output while also improving the engine's thermal efficiency.

- Exhaust Gas Recirculation

- STARC (Strong Tumble & Appropriately stretched Robust ignition Channel) is a combustion concept announced by Nissan in 2021, delivers impressive thermal efficiency