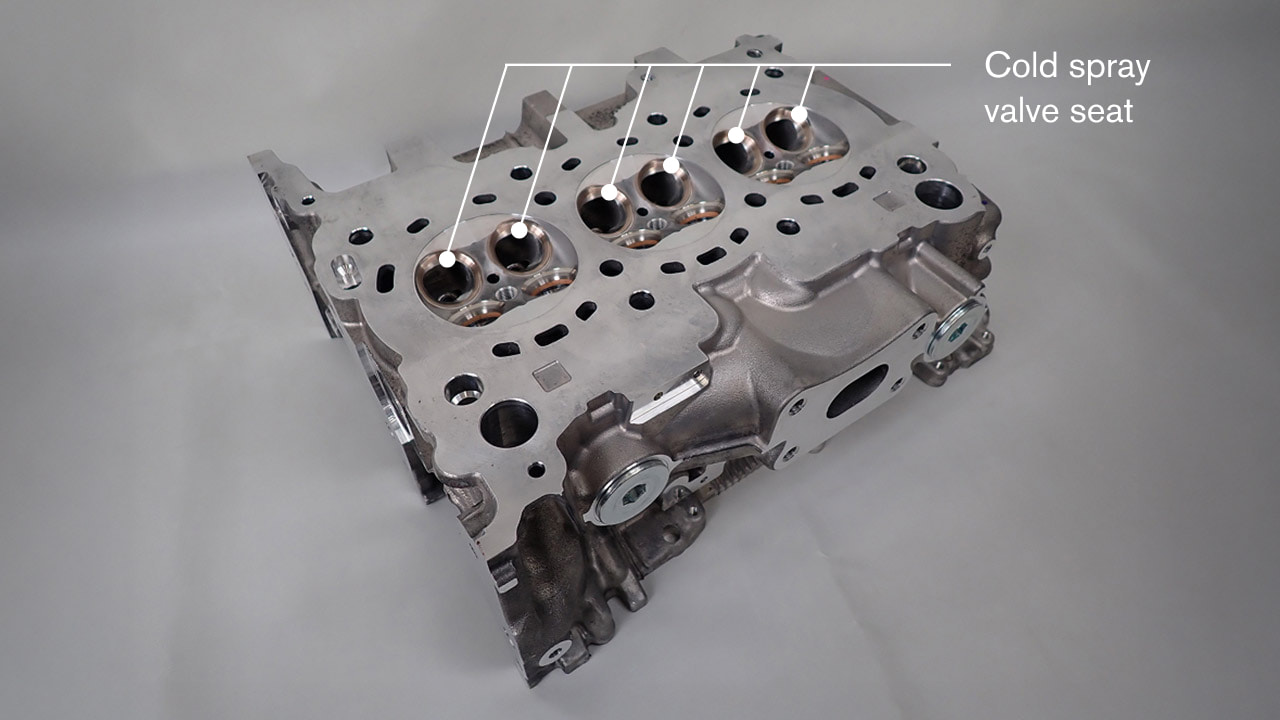

Cold spray valve seat

The world's first cold spray valve seat structure supporting high efficiency in e-POWER dedicated generator engines

e-POWER is Nissan's unique hybrid powertrain system that integrates a compact gasoline engine and motor. Since the engine only generates electricity and the vehicle is 100% driven by a high-output electric motor, it is possible to enjoy the driving experience of an EV. e-POWER has evolved its performance since its introduction to the market for the Japan market in 2016. The new 1.5-liter turbocharged engine (codename ZR15DDTe) employs Nissan's proprietary STARC*1 concept, which elevates thermal efficiency to 42% by stabilizing in-cylinder combustion. A key element of the STARC concept is minimizing airflow turbulence from the intake port into the combustion chamber, thereby generating a strong tumble flow. Nissan engineers addressed this challenge by developing and implementing a new valve seat using cold spray technology*2.

- STARC (Strong Tumble & Appropriately stretched Robust ignition Channel) is a combustion concept announced by Nissan in 2021, delivers impressive thermal efficiency.

- Cold spray is a coating technology in which powdered materials are sprayed at supersonic speeds to form a solid layer. Since the 2000s, it has been widely adopted in the aerospace industry, energy, heavy equipment, oil and gas, and other manufacturing industries, provided an advantage in terms of reliability and quality. It has recently gained attention for its applications beyond surface treatment, including additive manufacturing.

New ZR15DDTe engine cylinder head

How cold spray helps enable the STARC concept

In conventional engines, the design of the intake port is constrained by the necessity of press-fitted, sintered valve seats, which limit the ability to optimize port shape for ideal tumble flow.

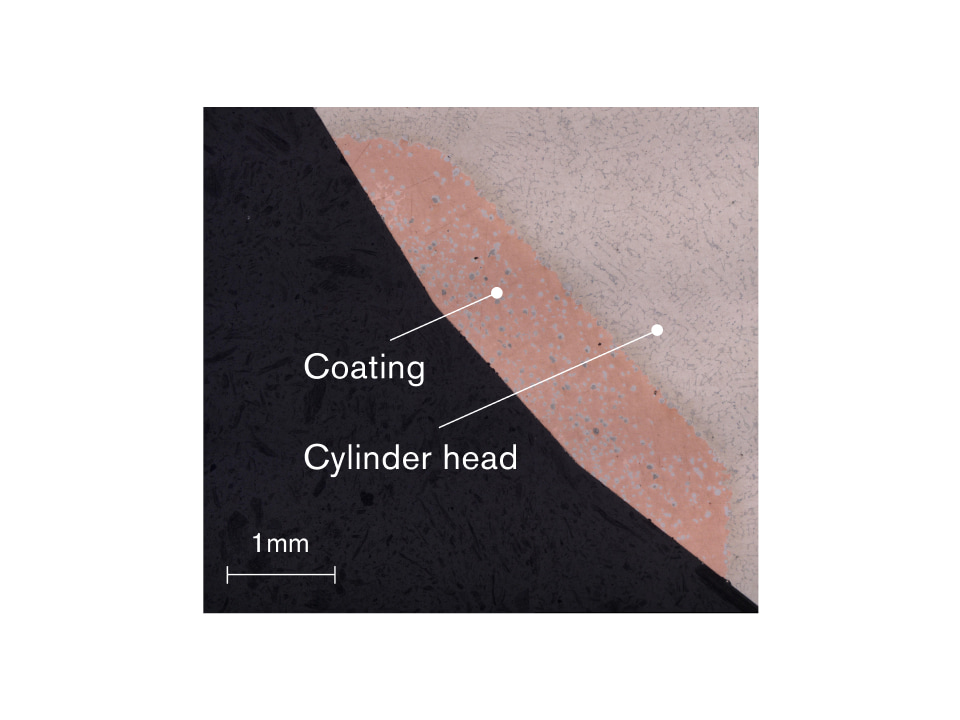

However, a novel valve seat using cold spray technology allows a coating to be directly formed onto the cylinder head surface by copper-based alloy which eliminates the need for a separate valve seat component and enabling the creation of an optimized intake port geometry.

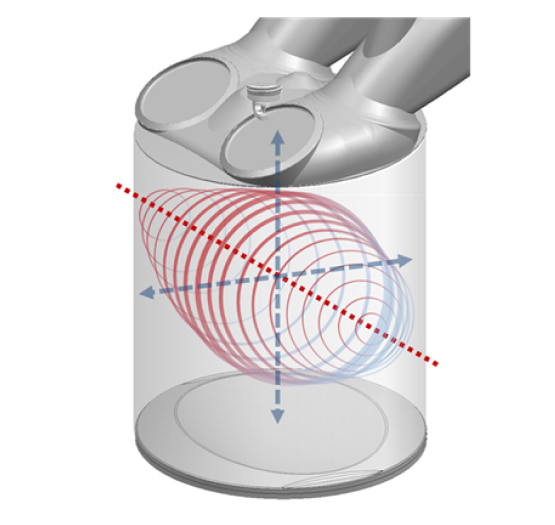

Image of tumble flow

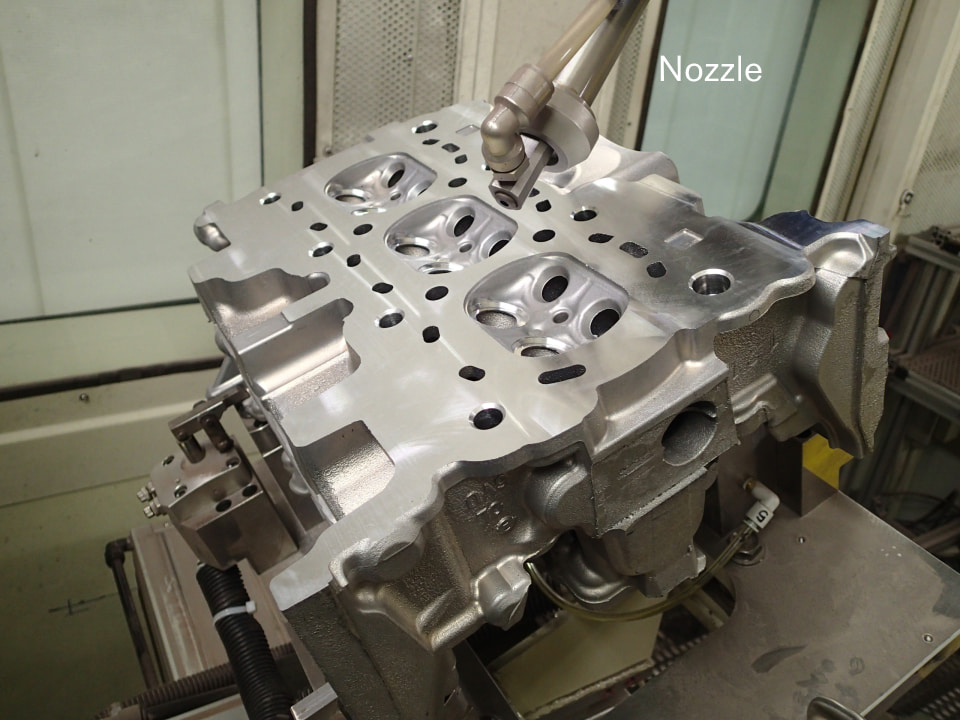

The process of applying cold spray valve seat

The new valve seat is produced by spraying dissimilar metal powders at supersonic speed onto the aluminum alloy cylinder head surface, forming a robust and durable coating that adheres strongly without melting the base material. This process prevents the formation of excessive intermetallic compounds and micro-voids (porosity) that are common in traditional fusion welding methods. Furthermore, compared to similar methods, its higher thermal conductivity enables improved cooling performance around the valves. As a result, cold spray coatings exhibit superior adhesion, durability, and reliability—crucial qualities for engine valve seats.

The process incorporates a specially developed cobalt-free, copper-based alloy with excellent thermal conductivity. The process incorporates a specially developed in-house nozzles, inspired by polishing techniques built up in forging mold production. These innovations reflect years of accumulated know-how, enabling the successful implementation of cold spray technology in engine valve seats.

Cross-sectional view of cold spray valve seat

Cold spray processing