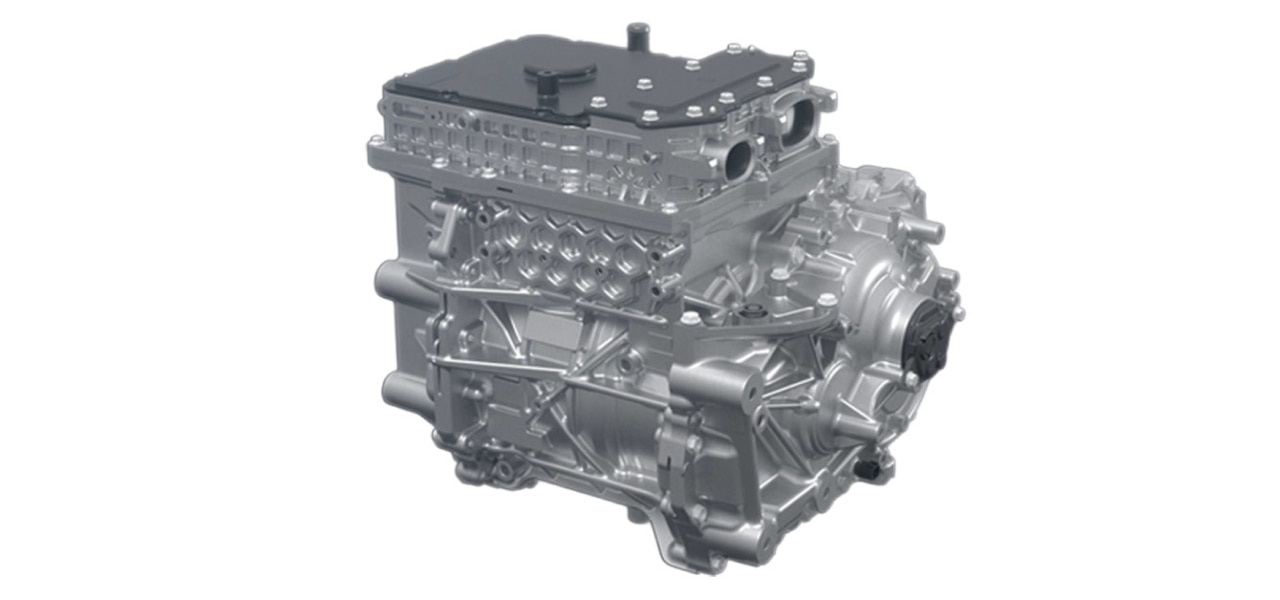

Electric vehicle powertrain (3-in-1)

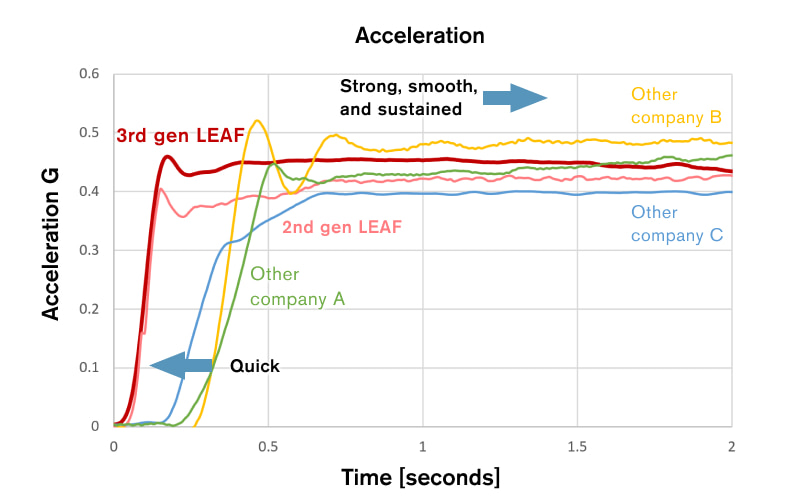

A new electric powertrain that elevates the EV driving experience

Nissan has a heritage of EV innovation spanning several decades. In 2010, Nissan introduced the LEAF, the world's first mass-market EV featuring a electric powertrain that would be the basis for Nissan EVs to follow. A unique benefit of an electric powertrains is potential to be used in a wide range of vehicles, from mini cars and compact cars to SUVs. The instant responsiveness of an electric powertrain can offer excitement and a heightened sense of control for those behind the wheel.

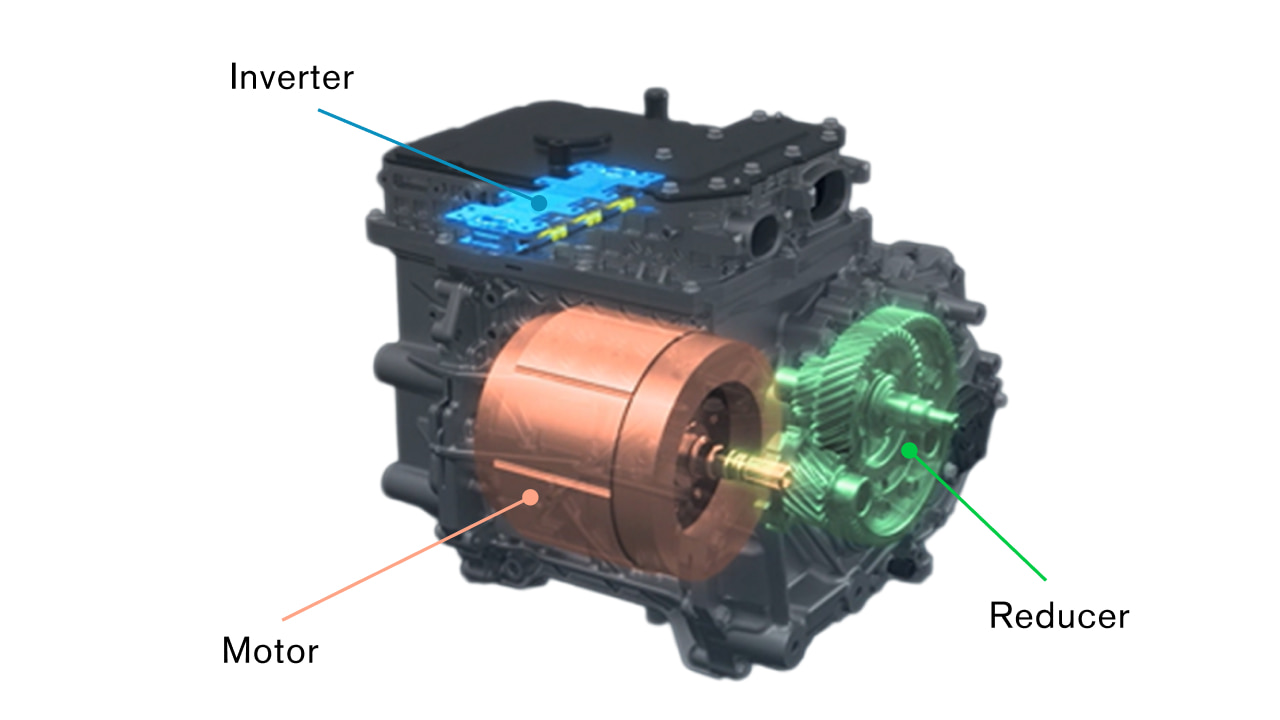

For the all-new, third-generation LEAF, a new electric powertrain was developed using a method called 3-in-1. The 3-in-1 EV powertrain incorporates three key components (the motor, inverter and reducer) in a compact form while also optimizing power performance, quietness and smooth operation. Power efficiency has also been improved, reducing overall operating cost for the owner.

System operation

An electric powertrain consists of three key components: a motor, inverter and a reducer. With Nissan's 3-in-1 powertrain design, the smaller size and increased structural rigidity results in less noise. With an advanced motor and inverter, the powertrain achieves higher output and efficiency, delivering more powerful and smoother acceleration along with improved energy consumption. The result is a responsive and highly refined electric drive.

System mechanism

Several enhancements have been incorporated with the 3-in-1 EV powertrain. To improve quietness, the rigidity of the electric powertrain was increased to suppress vibrations during operation.

In addition to the integration of motor, inverter and reducer to improve rigidity, the motor mounting bracket has also been redesigned to be more compact and to support rigidity.

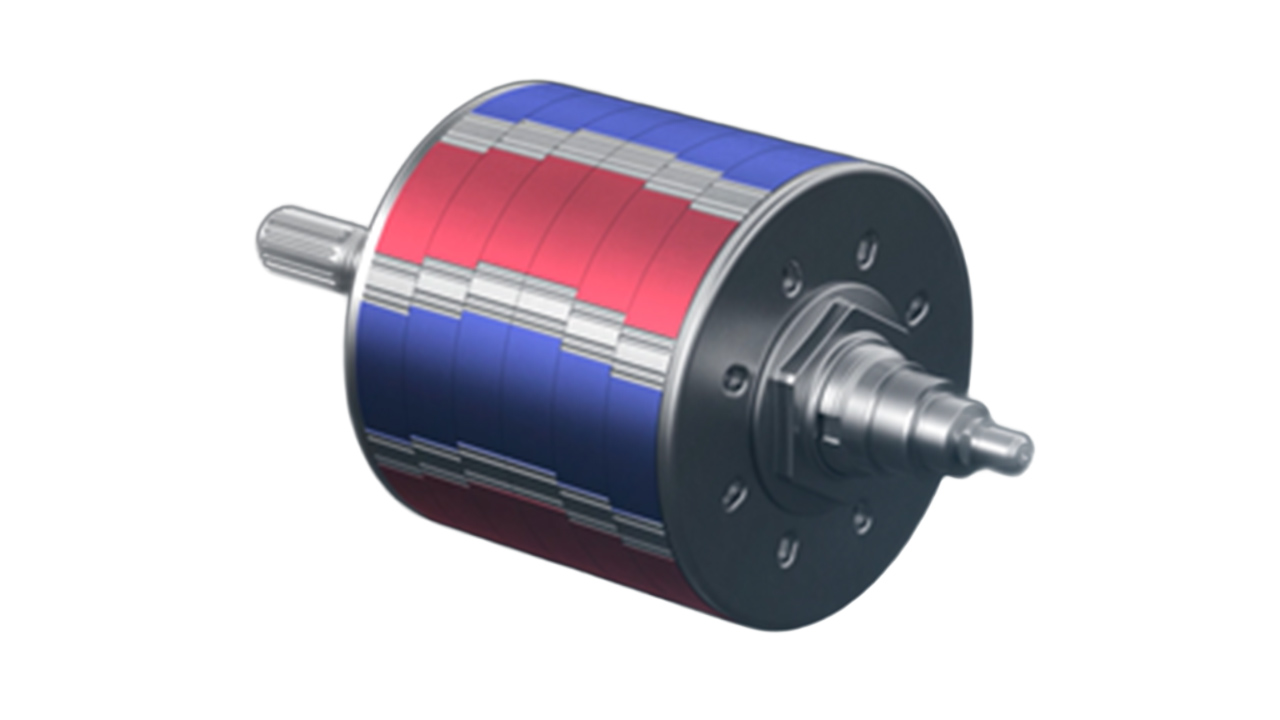

In addition, by adopting a six-stage skew rotor (slightly offsetting the rotor slots), the motor suppresses vibrations caused by magnetic forces. Furthermore, by using a press-fit structure for the internal case, the transmission of vibrations is also minimized.

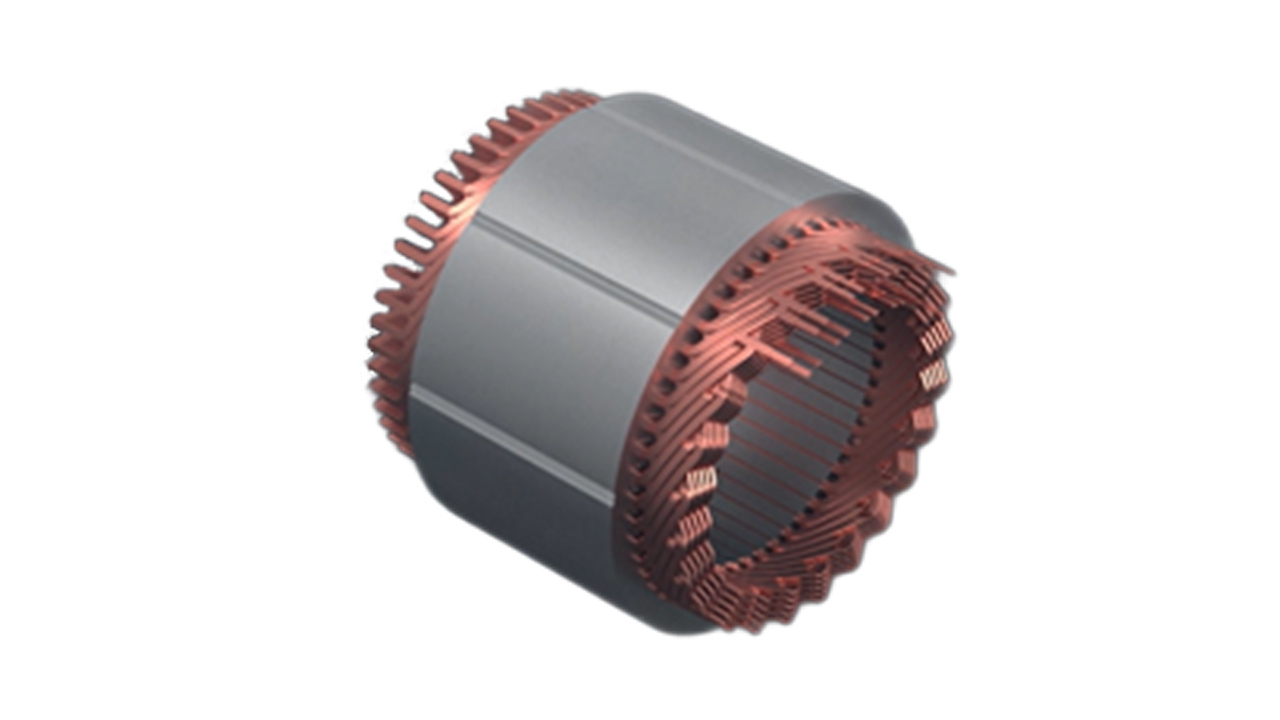

Six-stage skew rotor

Press-fit structure

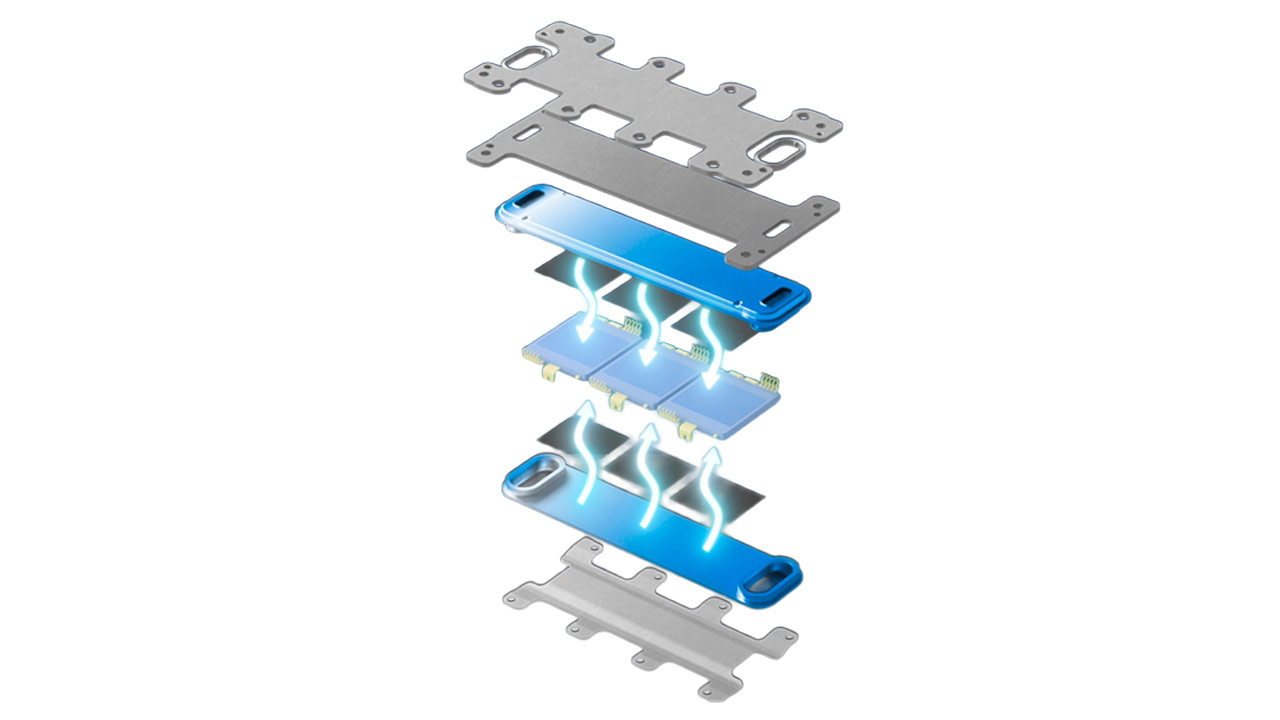

To improve acceleration performance and power consumption, engineers focused on increasing the amount of electrical current to increase output, suppress losses and enhance efficiency. A flat wire coil with a high occupancy ratio has been adopted to allow a large amount of electrical current to flow in a compact space within the motor. Furthermore, the inverter is equipped with a power module that features a double-sided cooling structure to improve efficiency, especially in the high-speed range.

Motor flat wire

Inverter double-sided cooling