information

![]()

![]()

01 STAMPING

Precise stamping for beautiful designs

02 BODY ASSEMBLY

Building solid frames for outstanding drive

03 PAINTING

Beauty born of a dust-free environment

04 ENGINE ASSEMBLY

Cutting-edge technology that underlies cars

05 ASSEMBLY

Assembly of thousands of parts

06 INSPECTION

People’s senses provide the finishing touches to cars with outstanding quality.

07 SHIPPING

Shipping cars overseas to people throughout the world

MOVIE

Movie of Nissan's car building process

DOMESTIC

PLANTS

Click map to display details of each plant. You can also apply for a plant tour from here

01IWAKI PLANT

The Iwaki Plant is a cutting-edge engine production plant that employs an integrated production system based on the highest level of automation and computers.

View the VQ engine production process on the tour.

Creative ideas and improvements are introduced on production lines, and you can touch tools actually used.

There is also a hands-on corner.

02TOCHIGI PLANT

The Tochigi Plant conducts the full range of operations from aluminum and steel casting to axle assembly and final vehicle assembly, mainly for Nissan’s luxury and sports cars, such as the FUGA and FAIRLADY Z.

On tours, elementary school students can view the assembly line while general participants can view both the assembly line and body line.

03YOKOHAMA PLANT

The Yokohama Plant, the leading unit plant, launched production in 1935 and now undertakes integrated production of engines and suspensions. See not only an engine assembly line but also the Nissan Engine Museum and the Guest Hall on the tour. The Nissan Engine Museum building was renovated to recreate the headquarters building when Nissan was founded, and it was certified as a historical building by the City of Yokohama.

04OPPAMA PLANT

With the introduction of welding robots and mixed production lines that make it possible to simultaneously build multiple models, the Oppama Plant has grown as a car assembly plant with some of the most advanced automation in the world.

The plant now undertakes mixed production of both electric vehicles and gas-powered cars.

Of course you can see the production lines, but you can also view the dedicated wharf from which up to 80,000 cars are shipped each month.

05NISSAN

SHATAI CO., LTD.

SHONAN PLANT

Responsible primarily for work cars, so-called light commercial vehicles (LCV), the Shonan Plant produces the largest number of models among Nissan domestic plants.

On tours, you can view the impressive welding robot and creative efforts undertaken on the production line.

06NISSAN

MOTOR KYUSHU CO., LTD.

The plant, which launched production in 1975, was the first car plant in Kyushu. On tours, you can see the manufacturing processes, painting and assembly. It also possible to view the dedicated wharf and parking area for completed car from the corridor.

07NISSAN

SHATAI KYUSHU Co., Ltd.

The Nissan Shatai Kyushu plant, the newest plant of global Nissan, launched full operation in January 2010.

The plant is in Kitakyushu, a region that offers major advantages for logistics that target Asia. Many car and car part manufacturers have launched operations in Asia, which continues to record prominent growth.

Located within Nissan Motor Kyushu (Kanda-machi, Fukuoka), the plant has a body building, a painting building, an assembly building, and an office building which serves as the headquarters for Nissan Shatai Kyushu.

* this plant does not offer tours.

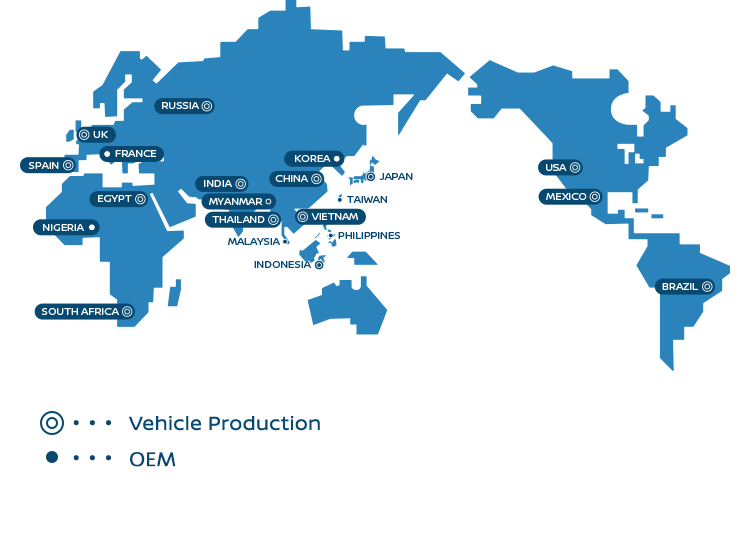

OVERSEAS VEHICLE

PRODUCTION