NISSAN PLANT

IWAKI PLANT

PLANT INFORMATION

ABOUT IWAKI PLANT

PROFILE

The Iwaki Plant, which began operations in January 1994, produces several Nissan engines including the optimized, fuel-efficient VQ engines, which have received several awards in Japan and the United States for their outstanding performance and development approach.

In 2020, three core concepts were implemented to further enhance the manufacturing process. These concepts focus on: creating a flexible assembly line where people and robots can coexist; new enhancements in line ergonomics, operational working environments, and a continual aim to produce engines with the highest quality and zero-defects as a world-class manufacturing plant.

DATA

| Area: | Approx. 201,500 m² Building floorspace: approx. 80,300 m² |

|---|---|

| Employees: | As of October 31, 2024: Approx. 860 |

| Production Capacity: | Approx. 560,000 units/year |

| Items Produced: | VQ engines, VR engines |

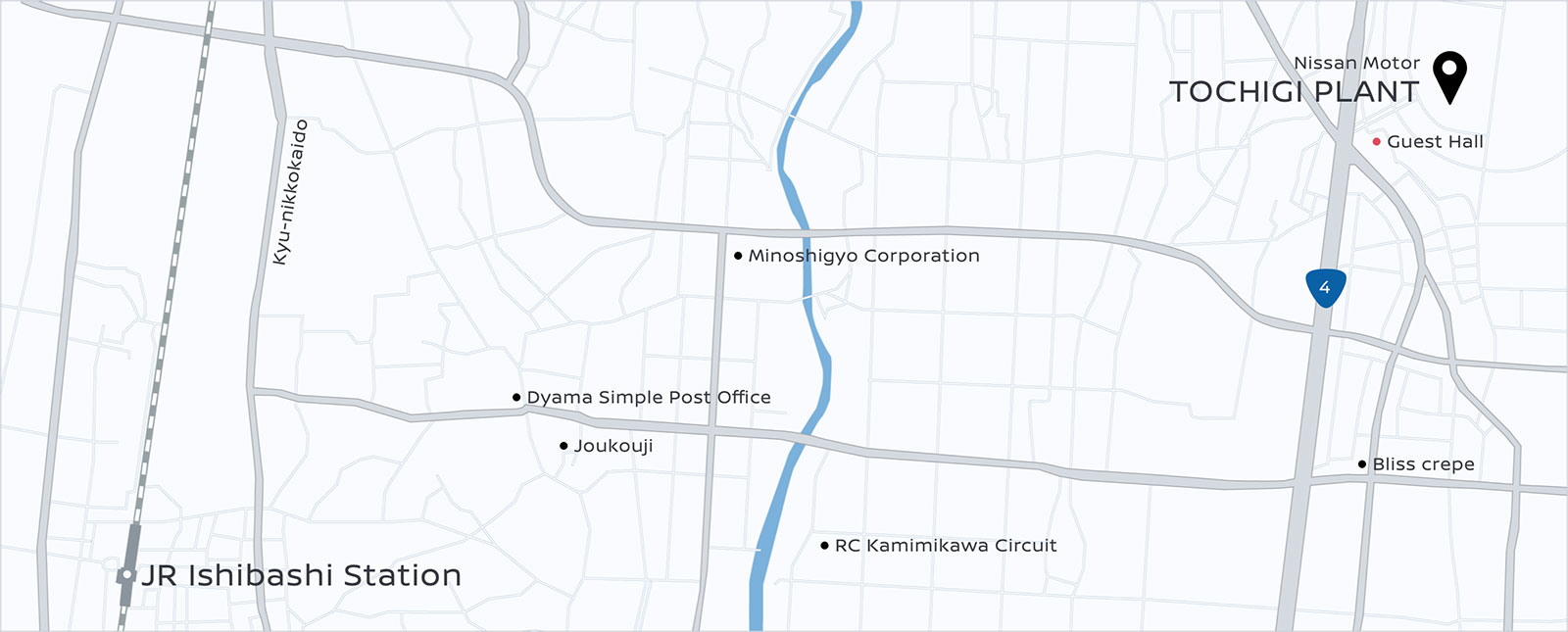

LOCATION INFORMATION

LOCATION / ACCESS

- ADDRESS

- 386, Shimokawa-aza-Otsurugi, Izumi-cho, Iwaki-shi, Fukushima 971-8183

- ACCESS

-

By train

Take the Ueno-Tokyo Line (Jobansen) Limited Express Hitachi (bound for Iwaki) from JR Shinagawa Station, Tokyo Station, or Ueno Station; get off at Izumi Station; and then take a taxi (about 10 min. ride)By car

From the Iwaki Nakoso Interchange on the Joban Expressway, take Prefectural Route 289, then head north toward Onahama on National Route 6 Bypass for about 12 km. The plant is located on the left side of National Route 6. - REQUESTS

- 1) Inquiries regarding plant tours

Iwaki Plant Guest Hall, Nissan Motor Co., Ltd.

+81 (0)246-75-1122

Reception hours: 9:00 ~ 17:00

(Excluding weekends and plant non-operating days)

2) Inquiries regarding the plant

Iwaki Plant, Nissan Motor Co., Ltd.

General Affairs Group, Administration Section

+81 (0)246-75-1123

Reception hours: 9:00 ~ 17:00

(Excluding weekends and plant non-operating days)

CAR LINEUP

MODELS PRODUCED

FOR DOMESTIC

Elgrand 3.5+ (VQ engine)

Elgrand 3.5+ (VQ engine)renewed October 2024

FAIRLADY Z (VQ Engine)

FAIRLADY Z (VQ Engine)renewed February 2025

Skyline V37 (VQ/VR Engine)

Skyline V37 (VQ/VR Engine)renewed February 2025

HISTORY

COMPANY HISTORY

| 1992 | Inauguration Ceremony |

|---|---|

| 1994 | Official production starts |

| 1997 | Cumulative production reaches 1 million units. |

| 1998 | Acquired ISO9002 certification, an international standard for quality control and quality assurance |

| 1999 | Acquired ISO14001, an international standard for environmental management. |

| 2003 | Updated to ISO9001, an international standard for quality control |

| 2008 | Cumulative production reaches 5 million units. For 14th year running, recipient of U.S. "Wards 10 Best Engines |

|---|---|

| 2011 | May 15 Complete recovery from Great East Japan Earthquake Disaster May 16 Cumulative Production reached 6 million units |

| 2015 | December umulative Production reaches 7 million units |

| 2016 | February Production of VR30 engine commences |

| 2016 | January Cumulative factory tours attended by 210,000 people |

| 2018 | January For 2nd year running, VR30 (INFINITI Q50/Q60) recipient of "Wards 10 Best Engines" |

STAFF COLUMN

PA (Plant Attendant) Blog

-

21Nostalgic Item

Do you know about this solid wax?

It is something that the father of a customer who participated in the Plant Tour used a long time ago, and he specially brought it because engines for the Skyline are being manufactured at the Iwaki Plant.

There were the logos of "Skyline", "GT", and "Nissan Prince" on the side, and the dent in the can; it made us feel the long history of the Skyline and a nostalgic atmosphere from that time.

Recently, some customers have attended our tour along with their beloved cars for the "Homecoming of the Engine".

Everyone, why don't you drive to the Iwaki plant while reminiscing about those days!

We look forward to your visits♪

May 16, 2025

-

20【The Fairlady Z Has Been Renewed!】

The displayed car "Fairlady Z" at Iwaki Guest Hall has been renewed!

The body color was changed from "Orange/Black" to a special paint color "Vibrant Red/Super Black 2-tone".

It is a very gorgeous red color.The Fairlady Z is equipped with the VR engine [VR30DDTT], which was manufactured at the Iwaki plant.

Please take a look at the Fairlady Z and the engine manufacturing lines at the Iwaki plant.

We look forward to your visit♪

March 26, 2025

-

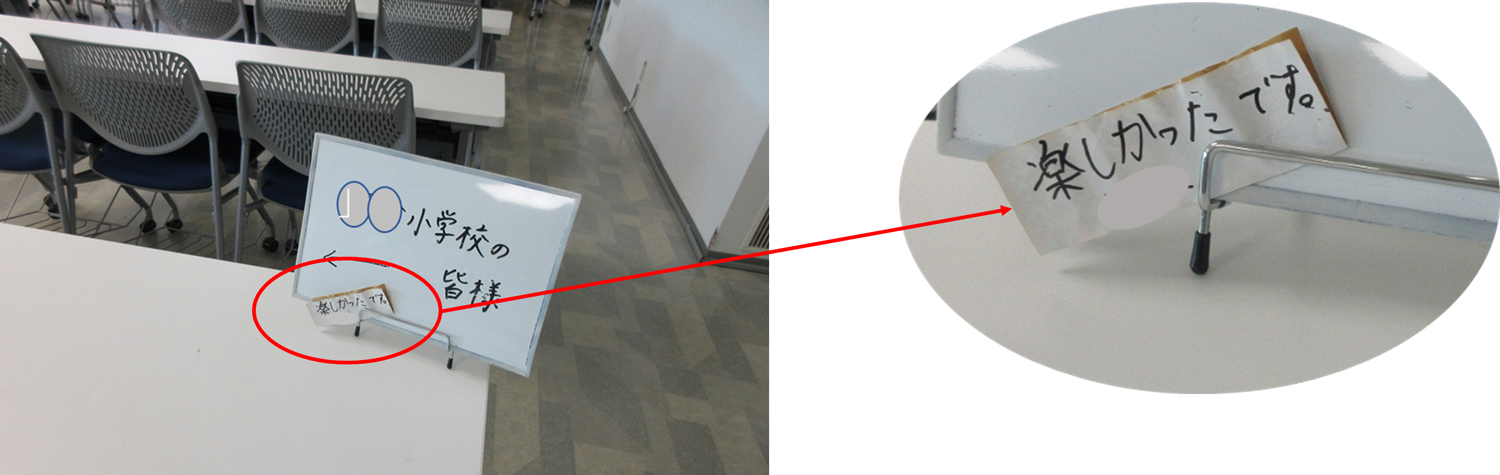

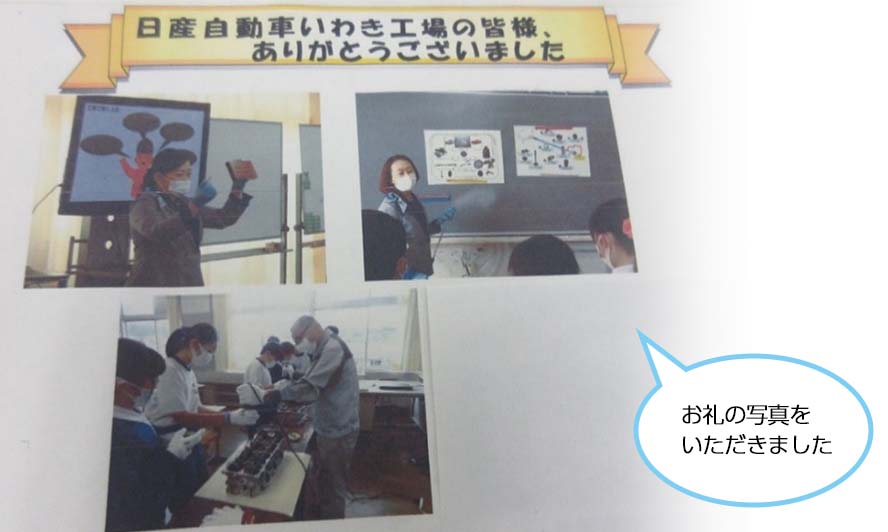

19【It means a lot to us♪】

We sometimes have received thank you letters after conducting online tours and on-site tours.

All the plant attendants read them carefully with joy♪The other day, we received this surprise message from an elementary school visited us!

When we were tidying up after the tour, we found a message saying, "It was fun."

It was gently tucked between a desk plate, and made all the plant attendants feel warm and fuzzy (^^)

Receiving happy comments means a lot to us.December 13, 2024

-

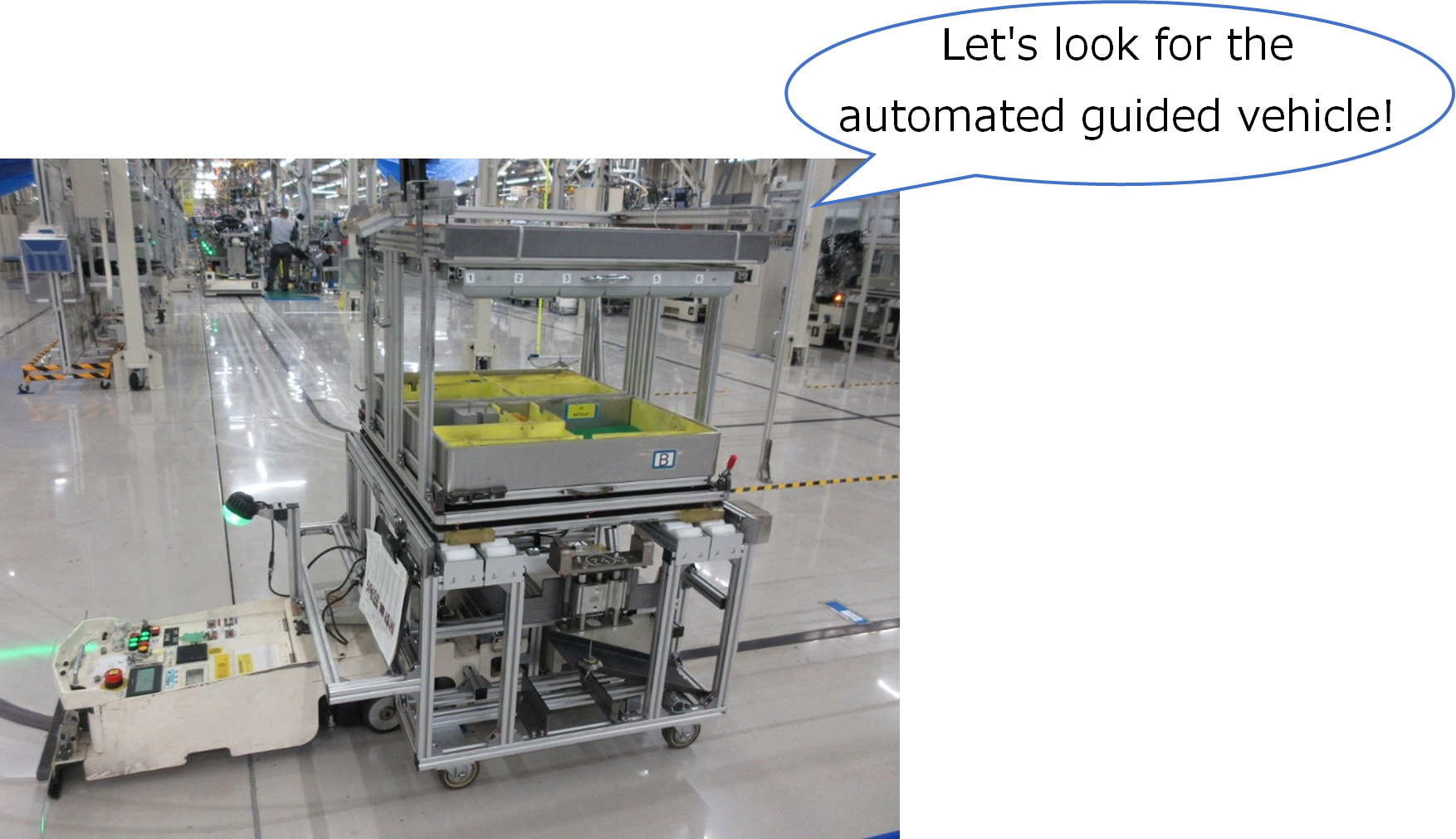

18New viewing area established in assembly line!

Iwaki plant is an engine assembly facility.

On this occasion, the viewing area for the engine assembly line, one of the highlights of the tour route, has been changed!

In the impressive assembly line, you can see large engines, automated guided vehicles transporting parts, and robots up close in the viewing area.Even if you say, "I've been there before!", please come again.

There are new discoveries waiting for you! We look forward to your visit.

November 19, 2024

-

17GT-R Premium edition has joined the lineup at Iwaki Guest Hall♪

A new GT-R has joined Iwaki Guest Hall.

It's the 2025 model GT-R Premium edition!The color is a special paint color called "WANGAN Blue”.

It's a fresh blue that changes its expression completely under sunlight and night lighting.The interior features the newly adopted "Blue Heaven" for this model.

The seats offer a luxurious seating comfort tailored by skilled craftsmen.When you visit, be sure to experience it♪

September 19, 2024

-

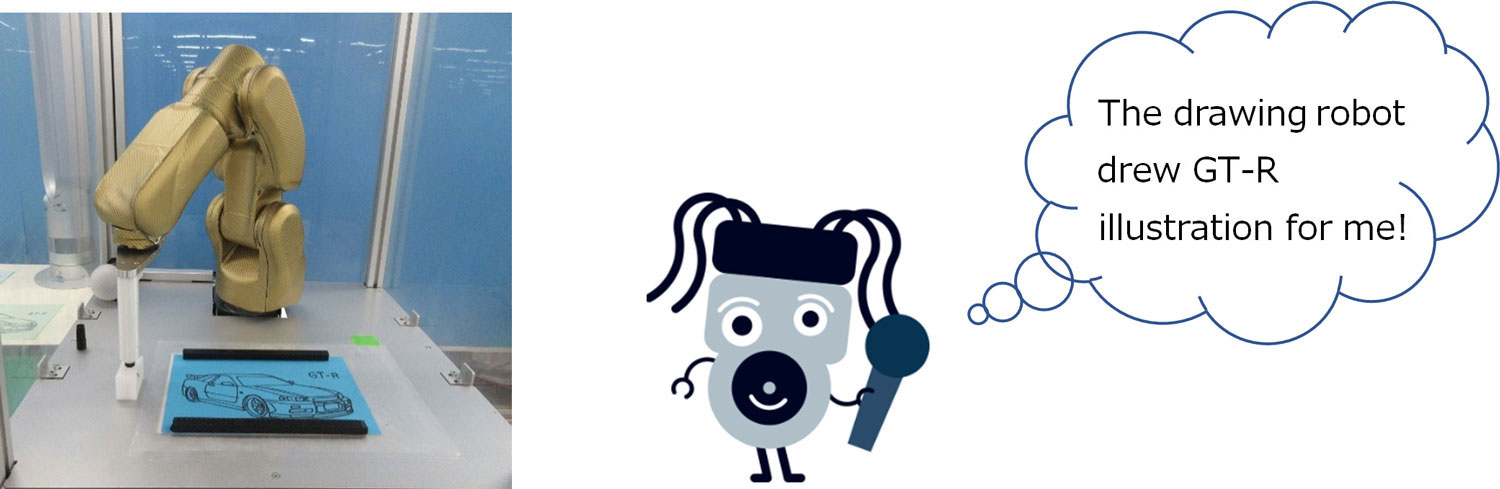

16🌻 Popular every year! Parent-child tour 🌻

During school's summer vacation, we are conducting parent-child tours which are popular every year♪

We have plant tours as well as experience corner where you can experience popular parts assembling.

Not only children, but also adults are able to enjoy such as coloring the illustration of a car drawn by the drawing robot.We are carrying out both online and on-site plant tours for parents and children during summer holidays.

Both tours are enjoyable events for families and we are looking forward to your participation![Young children are able to experience with their families]

August 8, 2024

-

15A lot of flowers will bloom from now on!

Cute flowers are blooming at the flower garden of Iwaki Plant🌸

Actually, ”Beautification Group” of Iwaki Plant are taking care of it.

They are not only cleaning the plant, but also make the plant area beautiful by planting flowers at the flower garden.

As the flowers are different according to the season, please visit Iwaki Plant and enjoy flowers blooming one after another.

May 24, 2024

-

14Introducing new members at our Guest Hall!

We have exchanged these EV cars, "LEAFe+G".

The body color changed to "vivid blue/ super black", and the blue color looks very beautiful✨

It made the Guest Hall gorgeous♪

One more thing...

New products are in stock at the vending machine for NISSAN goods!

Please also take a look at it.

March 29, 2024

-

13The new display car appeared!

FairladyZ which installed 3.0 liter twin turbo “VR engine” manufactured in Iwaki Plant has just joined in our Guest Hall.

New joining FairladyZ

(premium color: 432 orange)

We are displaying GT-R as well.

GT-R

(premium color: millennium jade)

By all means, please visit our Guest Hall on this occasion which you can watch sports cars “FairladyZ” and “GT-R”, and these cars are Nissan's pride.

December 20, 2023

-

12Let's put a commemorative stamp of the Plant Tour!

Do you know there are commemorative stamps of the Plant Tour?

As Iwaki Plant is manufacturing those engines for Fairlady Z, the stamps of “Fairlady Z” are prepared.

Please visit Iwaki Plant, and complete a smart car!

For your information, each Nissan Guest Hall has car stamps of each Plant origin.

Would you like to collect the series of stamps at every plant?

October 20, 2023

-

11Summer Special Tours have conducted.

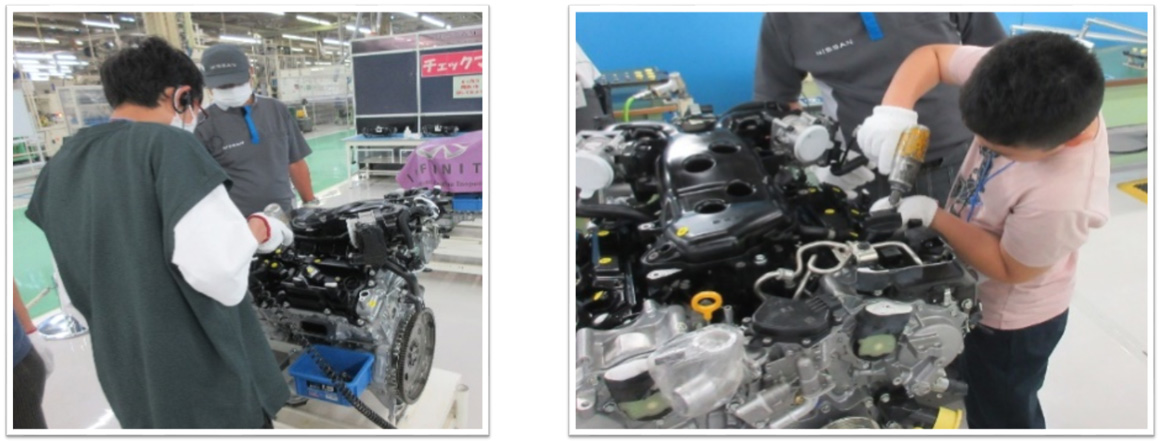

As summer special events, we conducted “Experience the assembly of Engine Parts and Family-Friendly Tour” in July and August.

Our guests have experienced assembling real engine parts to these engines that usually cannot be seen or be touched.

All of our guests from small children to adults experienced together and after that, we have received comments such as “It was a precious experience to assemble engines while feeling the atmosphere of the plant♪”

We were looking for quiz answers using “Let's find the cards” during the plant tour as well.

We will continue planning special tours on national holidays. Please participate!

September 5, 2023 -

10New Nissan Goods have just arrived★

Do you know that there is a vending machine installed in our Guest Hall?

[TOMICA Fairlady Z] and [Nissan folding ruler] are newly in stock♪

How about making use of these products to commemorate of your attending the plant tour?

There are various Nissan goods available!

July 4, 2023 -

09Our Guest Hall has become attractive!

Iwaki Plant Guest Hall looks shiny as the exterior has been painted and its NISSAN logo renewed.

We are currently displaying “GT-R Premium edition T-spec”, the sports cars that represent Nissan!

Why don't you take a photo with GT-R like Bear-kun below or sit in the car seats?

We look forward to your visit♪

-

08We have greeted a family as the 270,000th guests of Iwaki Plant Tours.

The cumulative total of Iwaki Plant Tours’ guests exceeded 270,000 in December 2022, and we took a commemorative picture with the family members♪

The family members love cars, and their children, the 3rd grade of the elementary school student, said, “I love cars, but I wanted to watch the manufacturing process of engines and I’d like to come back!” We are happy to hear that♪

All Plant Attendants would like to do our best to guide you with joy so that our tours are enjoyable one no matter how many times you visit us.

We look forward to welcoming you all. -

07We have new exhibition cars on display!

Fairlady Z

SKYLINE 400R

Fairlady Z & SKYLINE 400R which loaded 3.0 liter twin turbo “VR engine” manufactured in Iwaki Plant are newly displayed. We are looking out these cars everyday, saying “They are so cool!!”

In over 90 years of Nissan history, these cars have been loved by many fans for more than 50 years.

Do you know there are Hidden “Z” on Fairlady Z?

In this picture, there is another “Z” other than these marked with the red circles.

Why don’t you come and find out one more? -

06Greeting with Seasonal Tradition

Beautification Group at the plant is preparing the Seasonal Garden to greet our visitors, the Garden was drawn using the line powder; it is known to draw a line at ground. Please take a look at the Garden from the bus window when you visit us, it changes every month.

We are looking forward to it next month!

Pink cosmos are blooming in green turf and they look refreshing.

-

05The gentle light of the reborn light

This object is called "Reborn Light" and is reborn as a streetlight by reusing the battery that has finished its role as an electric vehicle and installed the town of Namie, Fukushima where was recovered from Tsunami damage. They are also installed in Nissan Iwaki Plant and these gentle lights are always watching over the area.

-

04Preventing Heat Stroke

Nissan Motor Factory Tour has prepared "Salted Candy" to prevent heat stroke.

The package features a cute character of the factory tour.

We will continue to use such characters in our tours.

-

03Heading out to provide outreach lessons

We thought about a way to communicate the ethos of Monozukuri to school children who want to come on a plant tour but are unable to, as we were so keen to accommodate them. So, we decided to provide outreach lessons from the plant at elementary schools! We loaded some 30kg of kit into the car, which is not normally available for factory tours, and set off.

All the children, including the teacher, were "bright-eyed" and earnestly engaged in the outreach lesson. Seeing this made all of us in the PA department very happy.

-

02A headteacher who loves Nissan Skyline

This week, teacher in charge of a group of elementary school children visited the plant, who was a major Nissan Fan. He has only ever driven Nissan cars, and his current beloved car is a Skyline. He has driven it for 13 years, clocking up 300,000 km. Although he has made various repairs to the vehicle, he has never had to repair the engine, and was kind enough to say that "Engines made in Iwaki are superb!". In line with the plant tour, the headteacher used his own car to give the children a special class beforehand. Upon seeing the car, the children gleefully remarked, "It's the same as the headteacher's!"

-

01PA Gathering! First attempt at online training!

Once a year, PAs from all plants in Japan get together to hone their skills in guiding factory tours.

Every year, we visit guest halls around the country to conduct the training, but this year, we conducted a three-day training session online! We were a little unsure as this was the first time to conduct online training, but learned a lot of things such as how to welcome people and about Nissan's technology, and found many improvement points and things to discover. In addition to the resumption of offering factory tours , online tours have also started at the Kyushu and Oppama sites, and tours are now available in a new style at each guest hall.

Please don't miss it !

We're looking forward to taking you on ever-more enjoyable and fulfilling tours!

2019 Training in session (at Kyushu Guest Hall)

2020 Online Training

PLANT ACTIVITIES

EVENT INFORMATION

LATEST EVENT INFORMATION

There are no events currently scheduled. We will update and inform you of future events here.

PLANT INITIATIVES

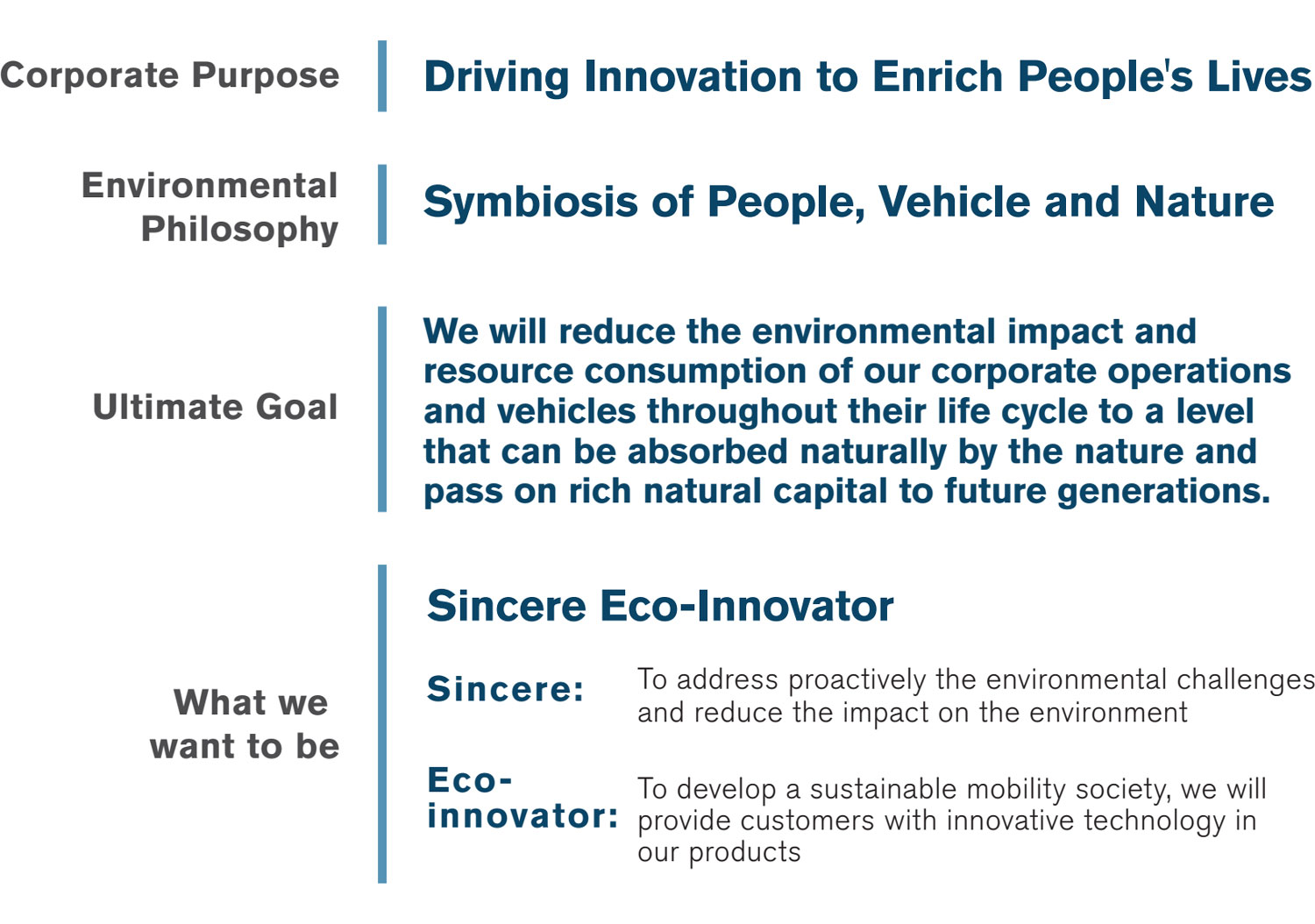

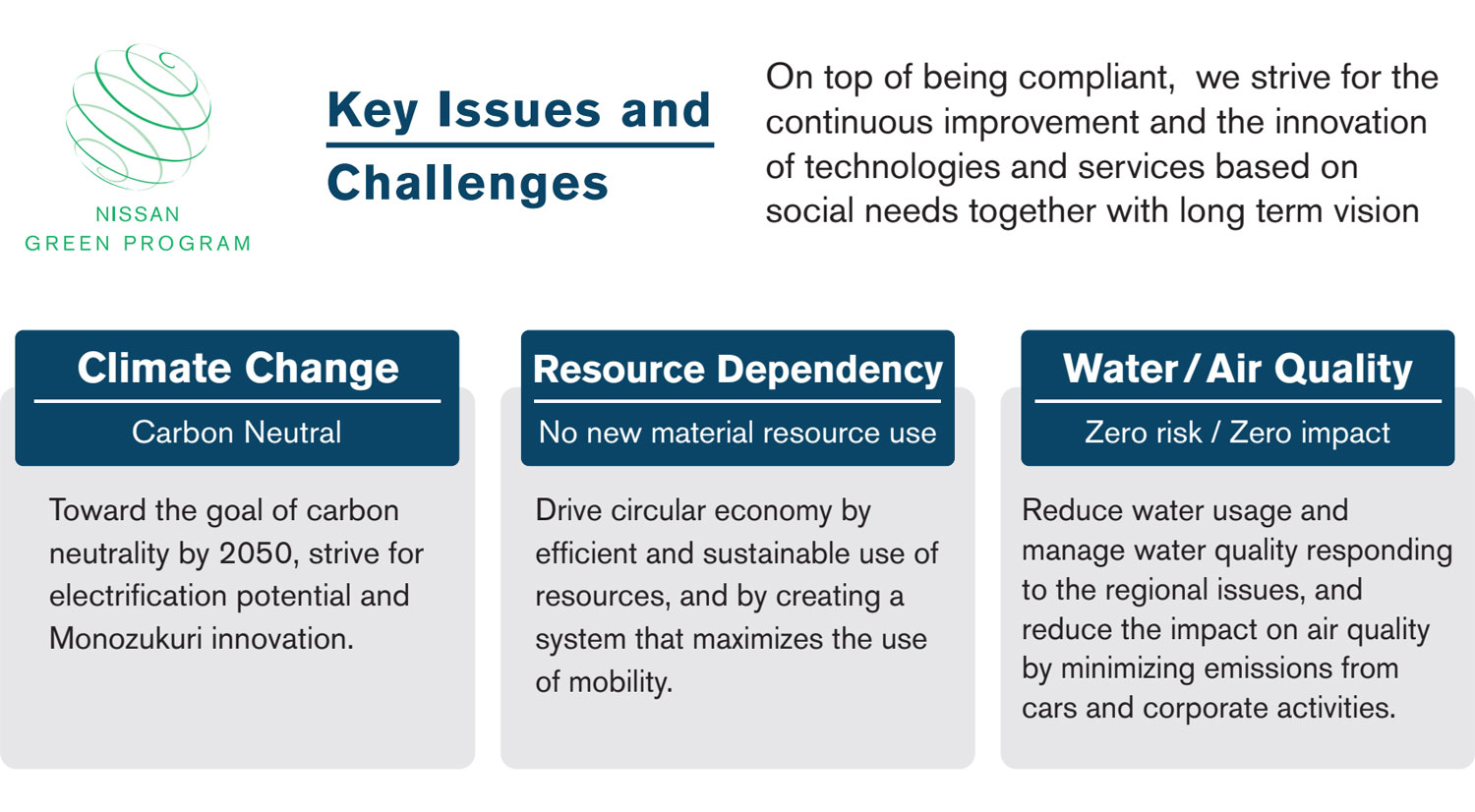

ENVIRONMENTAL INITIATIVES