- Permanent magnet motor

- Magnet temperature

- Permanent demagnetization

- Temperature estimation

- Limit design

- Improved output

- Reduced cost

This technology prevents torque drops at high temperatures by controlling the current in response to changes in temperature.

- ● Enables real-time, high-accuracy magnet temperature estimation as an on-board technology.

- ● Reduces motor costs by lowering the required heat-resistance rating of the motor.

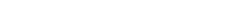

This technology uses a program that estimates magnet temperature based on the impedance (voltage to current ratio) of the current flowing through permanent magnet motors. It detects impedance from the current sensor equipped on the stator coil terminal, so operates entirely using a program that runs on the motor ECU without any additional hardware to make calculations.

↓ This table is cited from the provided materials. When an item is NOT applicable, it is clearly marked as “N/A”

| Technical name | Motor magnet temperature monitoring technology |

|---|---|

| Overview | This technology estimates temperature changes in magnets using high-frequency impedance. |

| Effect |

|

| Application track-record | N/A |

| Licensing | Patents Know-how Know-how related to tables for estimating magnet temperature |

| Companies for which licensing is recommend | (1) Manufacturers who develop motor ECUs. (2) Manufacturers who develop and manufacture products and equipment that use high-reliability motors. |

| Others |

- Electric motorization

- Software

- Material and material technology

- Measurement and inspection technology

- Facilities and equipment

One driver for this technology development is the understanding that magnetic forces weaken as magnet temperatures rise, which in turn lowers motor torque. Likewise, it is necessary to ascertain magnet temperatures and run motors in a way that avoids applying excessive reverse magnetic fields to the magnets at high temperatures. However, as motor magnets are embedded in the rotor, direct temperature measurement is difficult, which has led to a demand for a technology that estimates magnet temperatures.